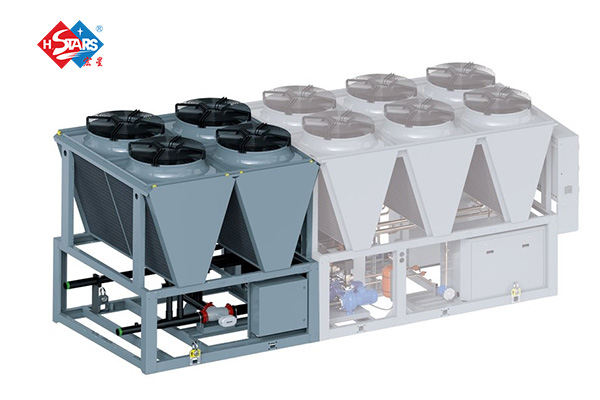

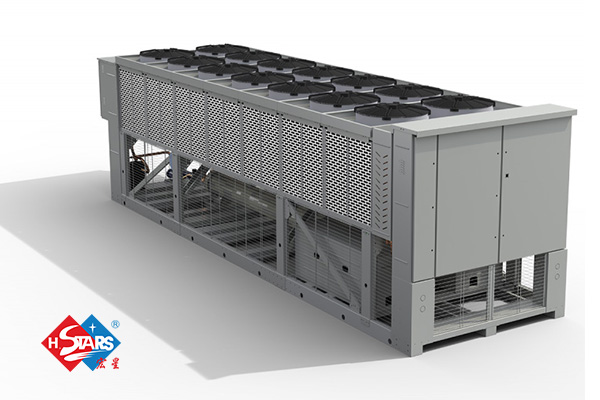

When it comes to cooling large spaces, a free cooling chillers is an ideal solution. free cooling chillers use a combination of natural elements to cool air and water, making them a more efficient and eco-friendly way to cool large areas. In this article, we will take a look at the benefits of using a natural cooling chiller and why it is the right choice for your cooling needs.

First and foremost, natural cooling chillers are more efficient than traditional air conditioning systems. By using natural elements such as ground water, wind, and solar energy, natural cooling chillers are able to cool the air in a space more efficiently than a traditional system. This means that you will be able to save on energy costs, as natural cooling chillers are more efficient and can cool a space faster and more effectively.

Another great benefit of natural cooling chillers is that they are more eco-friendly. As they do not rely on traditional energy sources such as fossil fuels or electricity, natural cooling chillers are a much more sustainable choice. This means that you will be able to reduce your carbon footprint and help preserve the environment.

In addition to being more efficient and eco-friendly, natural cooling chillers are also much quieter than traditional air conditioning systems.

评论

发表评论