How to design a water chiller system with AHU for pharmaceutical factory workshop | Hstarschiller.com

Nowadays, it’s become more and more aware of pharmaceutical enterprises to realize the significance of building an efficient and green to environment cooling system in the factory, because it can not only help the owner to save the running cost but also contribute to the society by reducing the emissions, especially for those developed countries .

But how to design a simple but energy saving cooling system with clean workshop? Below we are going to give you a real case for your reference to help you understand well, especially for those are quite new to the water chiller system field.

Firstly,this project has been done by H.Stars Group ,including the system design,equipment manufacturing and installation etc. Below is the detailed project overview to help you understand the owner’s requirement .

Project address: one of the pharmaceutical factories located in China

Project desire: Requesting a constant temperature with humidity for oral solid preparation workshop

Project Requirement details

Building | Area | Temperature | Humidity requirement/% | Air change times | Cleanliness level | ||

Summer | Winter | Summer | Winter | ||||

Clean workshop | 1600m2 | 24℃± 2℃ | 18℃± 2℃ | 50~70% | 50~70% | 15 times/h | 100,000 level |

Secondly,here are H.Stars Group scheme designs details:

System heating and cooling design:

The cooling system is adopting "H.STARS" water-cooled screw chillers, and the heating source is also from H.Stars chiller (heat pump )

It’s designed with supply and return water temperature of 7℃/12℃ in summer for cooling and 45/50℃ in winter for heating

Water system: A closed mechanical circulation system is adopted, and two vertical circulating water pumps (1 used and 1 backup) are installed into the chiller unit and controlled intelligently by the chiller system.

Air terminal system design: the air side adopts H.Stars horizontal constant temperature and humidity air handling unit with secondary air return system.

Cooling water source: "H.STARS" low-noise circular cooling tower is adopted to solve noise complaints in residential areas.

Control system: H.Stars self-programmed control system ,it adopts Siemens PLC with fully automatic control

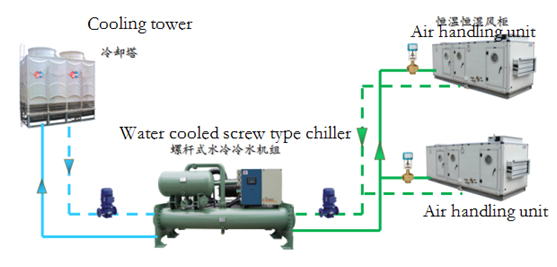

Thirdly, below is the system schematic diagram

Fourthly, below table is the equipment configuration

Equipment Name | Equipment Parameter | Quantity | Remarks |

Cooling capacity: 373kw | 1set | ||

Round cooling tower | Water flow: 100m3/h | 1set | |

Air flow: 35000m3/h | 2 set | One use and one backup | |

Water Pump | Water flow: 91m3/h | 2 set | One use and one backup |

Water Pump | Water flow: 81m3/h | 2 set | One use and one backup |

Fifthly, H.Stars designed energy-saving details as below

1). The air system is designed with a secondary air return system to balance cooling and heating and reduce operating costs.

2). The purification horizontal air handling unit adopts the dew point air supply method, which greatly reduces the energy loss caused by dehumidification and reheating, and saves more than 30% of the annual cost compared with the ordinary method.

3). Combination of main and end, air and water joint adjustment; under the premise of ensuring indoor comfort, based on the end load demand, the air system and the water system are adjusted synchronously.

4). The fresh air equipment has a clean and dehumidifying function to ensure the quality of fresh air and achieve energy-saving purposes.

Sixthly, H.Stars self- programmed advantages

1)Stable and reliable performance: It adopts screw compressor with stable performance, low noise and long service life.

2)Independent property rights: Unique internal oil return design of the evaporator, low oil return load and high efficiency.

3)Safe and reliable: The unit is equipped with multiple protections to ensure operational reliability.

4)High efficiency and energy saving: Equipped with flooded type evaporator, the energy efficiency of the whole machine can reach 5.5 cop.

5)Intelligent control: The equipment adopts PLC automatic control, no need to take care of the machine room.

Last but not the least, H.Stars onsite real photos for your reference:

评论

发表评论