How H.Stars help you save energy by adopting water-cooled magnetic oil free centrifugal VFD chiller - Hstarschiller.com

As we all know , the society is urging all enterprises to fulfil their obligation on energy saving to keep the earth green for our next generations. H.Stars Group has developed a ner product of magnetic VFD oil-free centrifugal chiller to be able to provide comprehensive partial efficiency IPLV of the unit upto 10, and the partial load energy efficiency value exceeds 13. The operating noise of the unit is only 76dB, and the frequency conversion starts, and the starting current is only 2A. Suitable for pharmaceutical factories, large commercial places, etc.

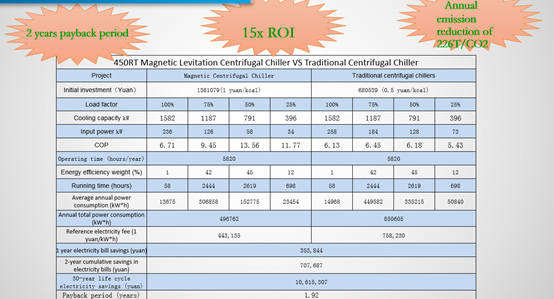

Electricity cost comparison table with traditional chillers

Unit cooling capacity range: 560KW-7800KW

Chilled water outlet temperature range: 5-20℃.

In addition to standard specifications, various types of non-standard units can also be customized according to user requirements.

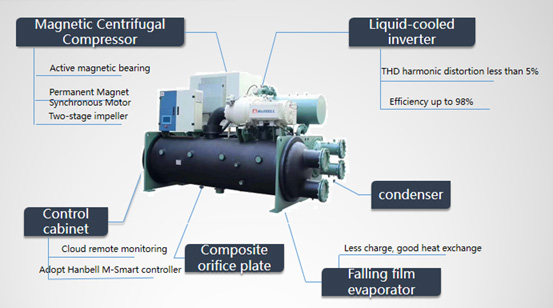

Structure of magnetic centrifugal chiller with VFD:

Features of Water-cooled magnetic centrifugal chiller with VFD:

1) COP up to 6.7 (GB condition)

2) IPLV up to 11.6 (AHRI condition)

3) The operating noise of the unit is less than 74dB(A)

4) Patented high-efficiency falling film evaporator

5) Oil-free design of the system, more efficient and energy-saving

6) Adopt Hanbell two-stage maglev centrifugal compressor

7) High-efficiency liquid-cooled inverter cabinet, small size and high efficiency

8) M-Smart intelligent control system realizes quick start, stop and restart

Advantages of magnetic centrifugal chiller with VFD:

1) High-efficiency

It can save 350,000 yuan in one year of operation and 700,000 yuan in two years. Running for 2 years can save a Mercedes Benz, 2 years payback period.

2) Safe & reliable

Magnetic centrifugal compressor;

Active magnetic levitation bearing &intelligent judgment of surge area;

Timely adjustment of speed and IGV to avoid surge;

3) Environmentally-friendly

Using the world's mainstream environmentally friendly refrigerant R134a, it has good comprehensive performance, and the ozone depletion value (ODP) is 0.

4)Condensation heat energy recovery, free and practical (optional)

Has a patent for heat recovery. Using the patented heat recovery device, the waste heat generated in the refrigeration process is recovered. That is, while providing customers with cold water, a large amount of hot water can also be supplied free of charge.

5)High efficiency heat exchanger with excellent performance

The high-efficiency heat exchanger independently developed and produced is used, and the liquid level is controlled by the electronic expansion valve combined with the liquid level sensor to ensure that the evaporator is always in a high-efficiency heat exchange state.

IPLV reaches 10.7, part load energy efficiency value exceeds 13

6)Magnetic oil-free technology, energy saving and noise reduction

No mechanical friction, noise less than 74dB(A)

Magnetic bearing, reducing energy consumption by 10%

The system is oil-free, reducing the heat exchange loss of the heat exchanger, improving the performance of the heat exchanger, eliminating the complicated oil circuit system and simple maintenance.

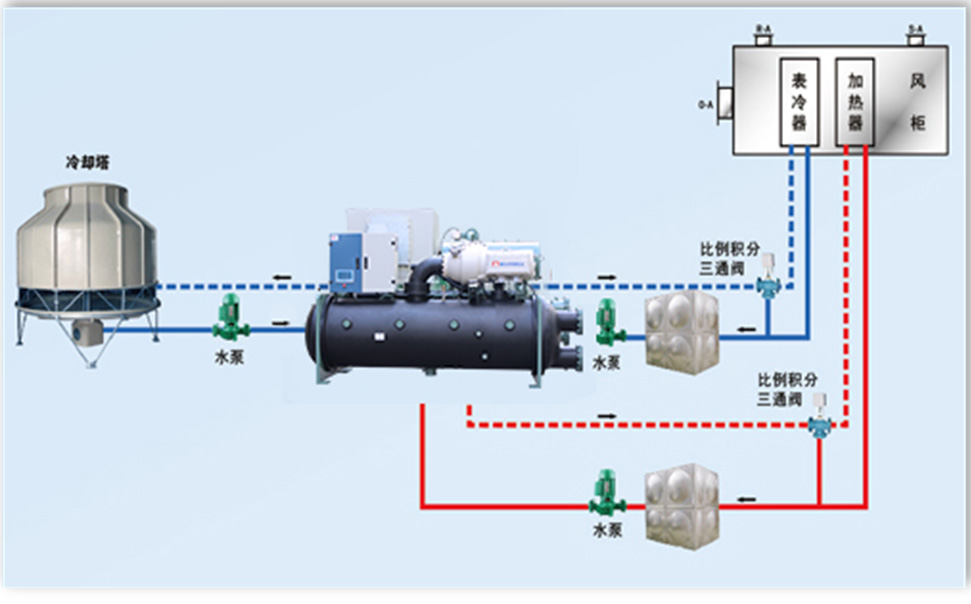

Flow diagram of magnetic centrifugal chiller

For more details, welcome to contact H.Stars engineer team for more materials at sales@hstars.com.cn or visit our site at www.hstarschiller.com .

For more details, welcome to contact H.Stars engineer team for more materials at sales@hstars.com.cn or visit our site at www.hstarschiller.com .Key words:

1) magnetic centrifugal chiller

2) magnetic VFD oil-free centrifugal compressor

3) high-efficiency falling film evaporato

评论

发表评论