How to design the energy saving cooling system for factory production line and office building | Hstarschiller.com

Project Overview

This project is for one of the new factory buildings for one of the 500 fortune company of Dairy industry . The factory new workshop building area is about 17,000 square meters, with a total of 2 floors. H.Stars Group has helped this company to design the energy saving cooling system by adopting low-temperature chiller and low-ambient temperature air source heat pump unit

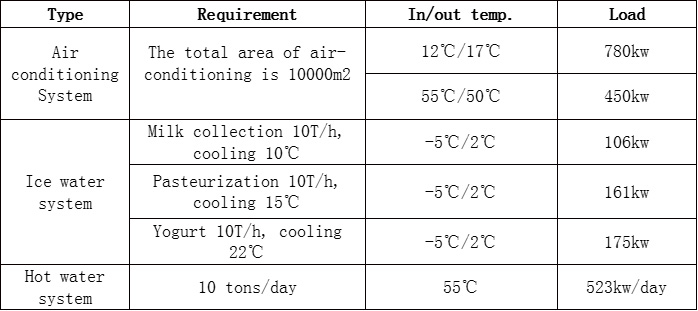

Project Requirement

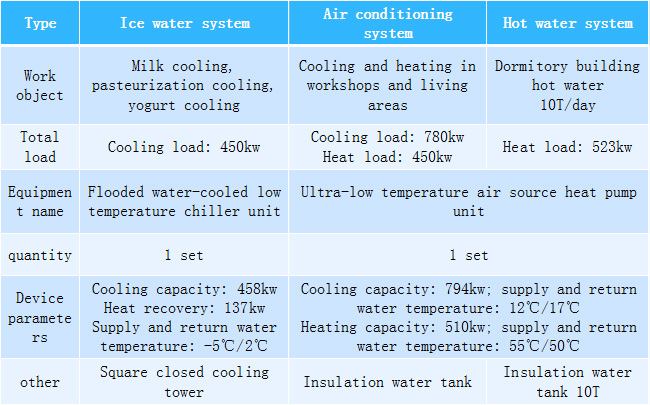

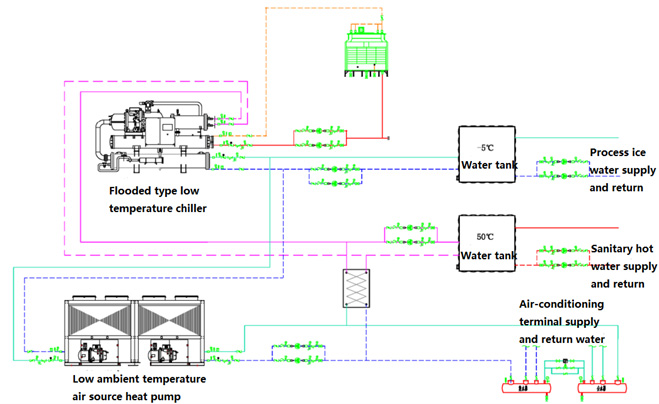

This project has air conditioning system, ice water system and hot water system, which has both cooling demand and heating load. The design of a system for the project can meet all the above requirements. Under the premise of ensuring safe and reliable operation, this scheme should balance the cold and heat as much as possible to make the system efficient and energy-saving. See the system flow chart for details.

The whole project designs a refrigeration station, equipped with a flooded type water-cooled low-temperature chiller (with heat recovery) + a low-ambient temperature air source heat pump unit (with cold recovery), and a square closed cooling tower. The system is designed with 2 thermal insulation water tanks, namely -5℃ ice water tank and 50℃ hot water tank.

Device Configuration

System flow chart

On-site real picture

Energy saving analysis

1. Winter energy-saving measures: When the ambient temperature of the room is lower than 0°C, the system preferentially uses a closed cooling tower to produce 2°C ice water to reduce the running time of the low-temperature chiller and reduce the load of the chiller by 15%.

2. The air-conditioning system is designed for high-temperature cooling in summer, and its water supply temperature is 12°C. The COP of the equipment is 35% higher than the existing use conditions, which reduces the initial investment and operating costs.

3. The low-temperature chiller adopts a large temperature difference design, the overall efficiency is increased by 7.5%, the pump power is reduced by 32% and the cost of supporting projects is 30%.

4. The low-ambient temperature air source heat pump unit is equipped with cold and heat energy recovery, one input produces two outputs, which optimizes the use of cold and heat and reduces initial investment and operating costs.

Advantage of solution

(1) Highly integrated: a set of systems integrates three functions:Coolin, heating and hot water.

(2) Green and environmental protection: No boiler room system is required for heating, and there is no emission pollution during use.

(3) Safe and reliable: The unit adopts dual-system loop design to ensure operational reliability.

(4) High efficiency and energy saving: the unit is equipped with cold and heat energy recovery, making full use of energy.

(5) Intelligent control: The equipment adopts PLC automatic control, no special person is required to supervise the machine room.

Solution Summary

The scheme design integrates a variety of systems with different working conditions and makes full use of the cold and heat energy of the system. The system design enables each unit to produce two benefits during operation. The energy discharged in the conventional scheme system design is reused, which greatly reduces the initial investment and operating costs.

For more details, welcome to contact us at sales@hstars.com.cn or www.hstarschillercom

评论

发表评论