What is the explosion -proof evaporative chiller? And how to produce a best qualtity of explosion proof Water Cooled Chiller Low Temperature Chiller?

In industries that need chillers to operate in dangerous conditions, explosion-proof chillers are the solution,because explosion-proof chillers have a reinforced design to protect the chiller’s components from ambient flammable materials that could cause an explosion. Explosion Proof Safety Chiller provides process or space cooling in harsh or explosive industrial applications. Chillers utilized within hazardous environments must have adequate physical protection and special safety features built-in to prevent damage to sensitive components.

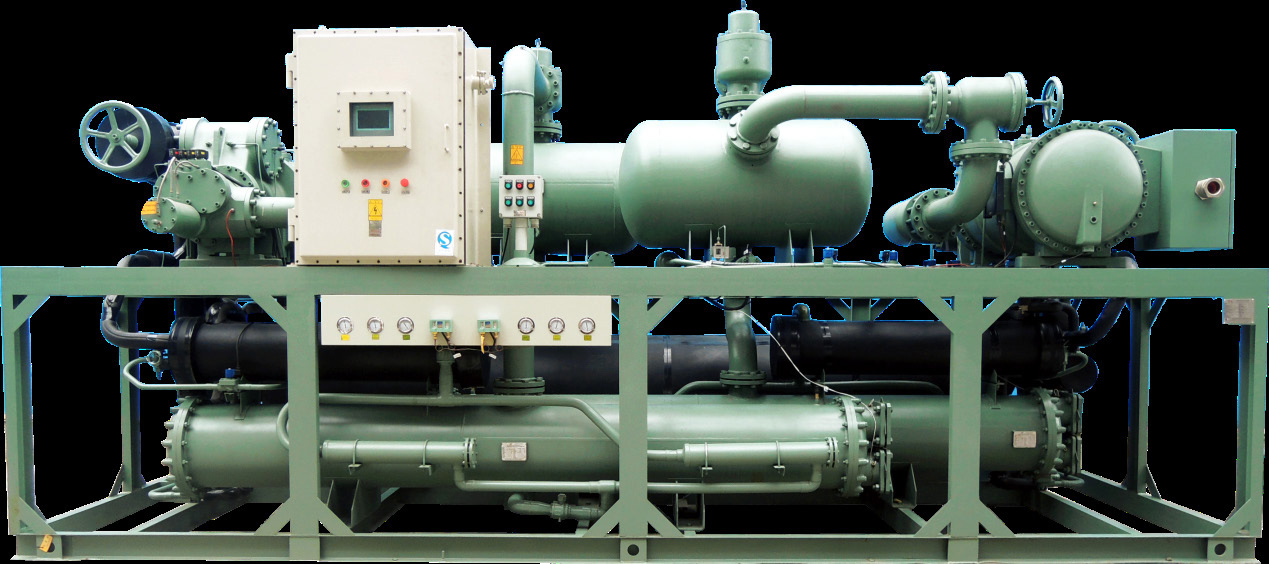

H.Stars explosion- proof equipment and its components are manufactured in strict accordance with relevant requirements of GB3836,a national explosion-proof standard, and explosion-proof certificate shall be obtained for it. It can be used in special places of high explosion or fire risk, as well as in ordinary circumstances. It is widely used in various industries, including petroleum, chemical, textile, printing, medicine, and food industries. Flameproof or positive pressure type of explosion proof equipment can be chosen based on the characteristics of the project.

H.Stars Explosion proof equipment has two explosion proof levels, Ex d IIB T4 and Ex d IIC T4; other explosion level is also available according to user requirements.

H.Stars unit features as followings :

•The skid-type unit is selected, which has stable performance, low consumption and energy saving, and high COP;

•The skid-type device has a compact structure, which is convenient for on-site management and maintenance;

•The unit is equipped with an evaporative condenser, which makes the operating cost of the system low;

•Save initial investment and space;

•Using Siemens PLC, the control is simple and reliable, and the system maintenance time is short;

Explosion-proof chiller

Evaporative condenser

• H.Stars Explosion Proof Water Cooled Chiller Low Temperature Chiller design advatanges as below:

• Adopt explosion-proof screw type low temperature chiller;

• The explosion-proof grade of the unit is d I I B T 4, and the protection grade is I P 5 5;

• Using Siemens PLC, the control is simple and reliable, and short time for system maintenance

•Using a high voltage of 10,000 volts, the high-voltage starting cabinet is independently set up, safe operation;

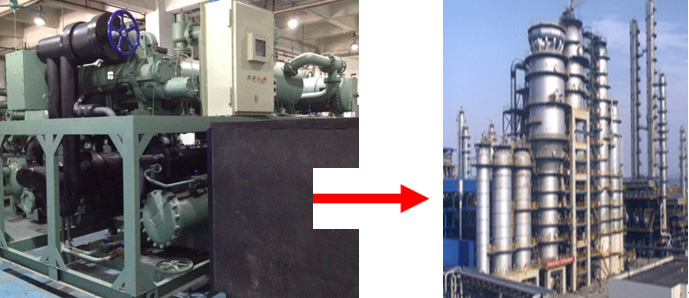

Low temp. explosion unit Catalytic cracking and other petrochemical equipment

Explosion-proof components

H.Stars Honorary clients in Daily Chemical Industry

H.Stars Group has focused on the R&D and production of refrigeration and heating equipment since 1992, professionally addressing customers' demands and tailoring products to customers' needs. For more details, welcome to contact us at sales@hstars.com.cn or visit us at www.hstarschiller.com

评论

发表评论