The air-cooled chiller is one of the chiller models. It cools the water at room temperature to a certain temperature through the compressor of the chiller to strengthen cooling of the mold or machine. It is used as a stand-alone machine. The heat sink is a built-in fan. There are three main mutual Linked systems: refrigerant circulation system, water circulation system, electrical automatic control system.

The air-cooled chiller is mainly used to cool the heating components of the equipment to ensure the normal operation of the equipment at a constant temperature. The air-cooled chiller is suitable for high-speed spindles, electric spindles, CNC machine tools, coordinate boring machines, grinders, machining centers, laser marking machines, laser engraving machines, laser welding machines, laser coding machines, laser cutting machines and other equipment. It is also widely used in the following industries.

Injection rubber process: cast film, composite film, blown film, bottle blowing, extrusion, injection molding, compression molding, etc.

Concrete mixing industry cooling and cooling system: beam making field mixing station, track slab mixing station, bridge pier mixing station, etc.

Industrial cooling system for photovoltaic solar industry (wire cutting machine, polycrystalline ingot furnace, PECVD, MOCVD, extended furnace, etc.)

Cooling system for chemical industry: electroplating, reaction kettle, reaction tank, soft water, circuit board, etc.

Cooling system for wallpaper coating industry: wallpaper, printing, coating, embossing, etc.

Cooling system for surface treatment industry: electroplating, coating, optics, oxidation, etc.

The air-cooled chiller has compact structure, small size, convenient movement and easy installation. Equipped with two working modes: constant temperature and intelligent temperature adjustment, the mode of intelligent temperature control can be adjusted to the corresponding water temperature as the temperature changes.

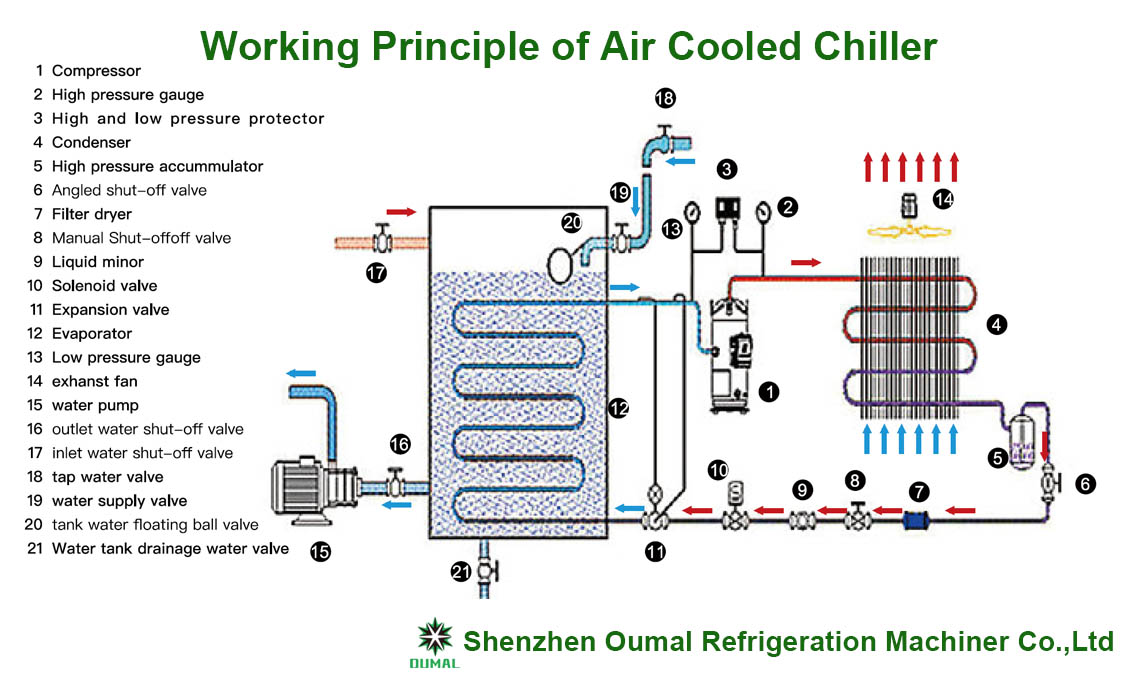

The working principle of air-cooled chiller:

Oumal air-cooled chillers use high-quality well-known brand compressors: Copeland compressor, Danfoss compressor, Bitzer compressor, microcomputer control panel, PLC control, Emerson, Danfoss and other brand refrigeration accessories, shell and tube type Heat exchanger or stainless steel plate heat exchanger, reliable quality. Contact us to get the air cooled chiller price.

评论

发表评论