H.Stars Group has recently signed a contract with 90℃ dual source heat pump unit project for one of the famous automobile factory to replace the traditional boiler.

1. Special design and customized size for easy installation.

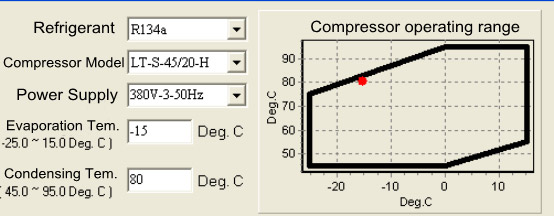

2. Adopt the special compressor of Hanbell high temperature heat pump, with high compression ratio, high energy efficiency, stable performance, multi-level energy adjustment, accurately matching the load change of the unit, low noise and low vibration. It has a wide operating range and can adapt to different operating conditions.

3. Environmental protection adopts environmentally friendly refrigerant: R134A.

4. It is matched with the high-efficiency heat exchanger produced by our factory and adopts the latest high-efficiency heat exchange copper tube to optimize the heat transfer efficiency, compact structure, strengthen heat transfer on the water side and the refrigerant side, reduce unit energy consumption and pipeline fouling .

5. Optional full cold recovery device to recover the cold energy generated during the use of hot water throughout the year to achieve zero-cost refrigeration.

6. The unit can produce 90 degree high temperature hot water.

7. The electronic expansion valve throttling device of the world's first-line brand is adopted

to ensure the quality.

8. Adopt low-noise high-quality fan, high air volume, high efficiency, sufficient dynamic pressure, IP54 protection level.

9. The finned heat exchanger has a V-shaped structure, high efficiency and simplicity, uniform wind speed, and stable heat exchange.

10. Reliable operation. The unit has a variety of safety protection measures to ensure the safe operation of the heat pump.

11. Intelligent control: Fully automatic microcomputer control, without manual monitoring, can realize remote or centralized management, saving management costs. It can be connected to the user's central control system, and the customer can understand the operation of the unit at any time. Customer needs: The process uses an 90°C dual source water air cold heat pump.

12. Technical advantages: high technology with non-standard customization.

How to make the product exceeds clients’ needs during production?

Real time monitor: Cloud service online to monitor the unit 24 hours a day.

Fully cold recovery dual source 90℃ heat pump: 90℃ hot water output and office air-conditioning at the same time

Low initial investment cost: Central air-conditioning only needs to add an evaporator on the basis of the process hot water , and the cost of the air-conditioning host can be saved by 70%.

Low operating cost: In summer, when you need to use air-conditioning for refrigeration, you can get air-conditioning cold water at zero cost.

Compact design smaller installation site: compact design, saving 50% equipment installation space

Low maintenance costs: machine maintenance workload and costs reduced by 40%.

Compressor selection table:

H.Stars Group products reference:

90℃ fully cold recovery dual source heat pump production with H.Stars Group Model 40STE-M390AHSR4

For more details on how to design and produce 90℃ dual source heat pump ,welcome to contact us at sales@hstars.com.cn

评论

发表评论