Since H.Stars Group has been established for more than 28 years so far, some of you might wonder how H.Stars produces a high quality water cooled chiller. Below is the detailed production process with strict quality control system and 100% testing before delivery.

1. Chiller Frame welding: clean the bracket and select the appropriate welding method according to the specifications of the welding materials and the technical requirements.

2. Chiller Bracket assembly: compressor, electric box, filter and other brackets are assembled and welded according to the required sizes from the drawing.

3.Shell and tube evaporator and condenser assembling process: the evaporator and condenser ,self-manufactured by UAR ,the subsidiary of H.Stars Group, is in welding process according to buyer’s requirements and H.Stars R&D team design.

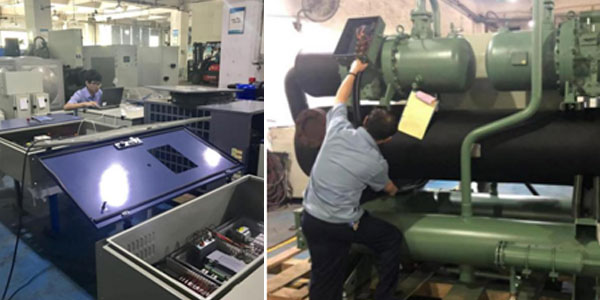

4.Sheet metal: the electric control box shell on the H.Stars chiller is designed and manufactured independently, and the quality is under the control of the factory.

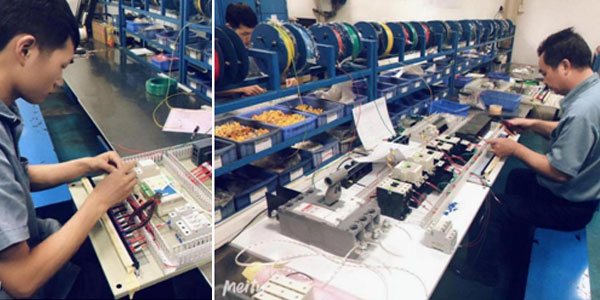

5.Layout of electrical components

According to the electrical schematic diagram, the layout of the electrical components and the wire slot is reasonably discharged on the electrical base plate, and the hole position of the corresponding component and the installation hole position of the wire slot are marked with a pencil and drilled. The layout requires that the components should not be hindered by space during operation, and there should be no possibility of touching the charged body.

6.Electric control box and compressor wiring: The controller imports the latest version of the program according to the factory operation standards before installation, and sets and adjusts the corresponding parameters according to the model parameter comparison table and customer requirements.

7.Refrigerant pipeline connection: For the vibration mode of the compressor, use a suitable shaped pipe to avoid resonance points near the power frequency; you can avoid resonance by adding weight.

8. Equipment testing station

National standard testing station, the factory equipment must be tested, and only after passing the test can the goods be delivered to ensure reliable product quality.

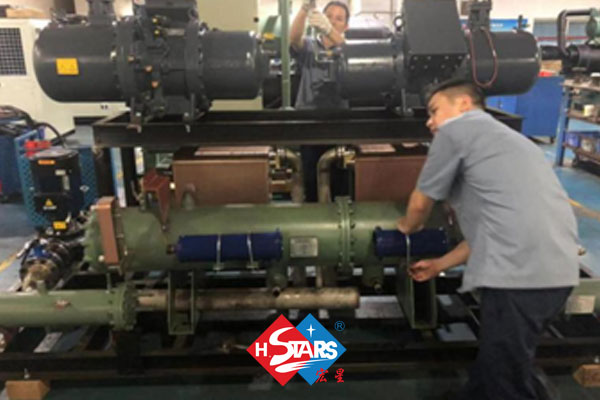

9.Large equipment testing center

H.Stars is capable of testing 800RT ~ 3000RT equipment, mainly detect centrifuge chiller and large chiller unit.

10.Insulation wrapping

According to the requirements of order, the thermal insulation will be wrapped accordingly. The chiller pump and related waterway system parts will be wrapped with thermal insulation after the unit passed the quality testing.

11.Outside spray

The main components the chiller except compressor, must be evaporator and condenser. According to customer requirements, the heat exchangers will be painted with required colors; After the heat exchanger is rust removed and gets polished ,it will be painted twice on the surface to secure the painting quality.

12. Packing Type

H.Stars is available to provide different packages according to exporting packing standard ,such as fumigated wooden cases and plywood boxes or reinforced shrink-wrap covering with industrial grade.

For more details welcome to contact us sales@hstars.com.cn

评论

发表评论