Ⅰ.Demand Situation

Food and beverage workshop ice water system engineering. The ice water system mainly meets the requirements of ice water on the production line. The required ice water temperature has two, one is 5 degrees ice water; the other is -5 degrees.

Ⅱ. Load Calculation

1.5 degrees ice water total cooling capacity is 1500KW

2.-5 degrees ice water total cooling capacity 750KW

3.12 degree water tank: 2*15m³stainless steel insulated water tank

4.-5 degree water tank: 2*15m³stainless steel insulated water tank

Ⅲ.Design Ideas

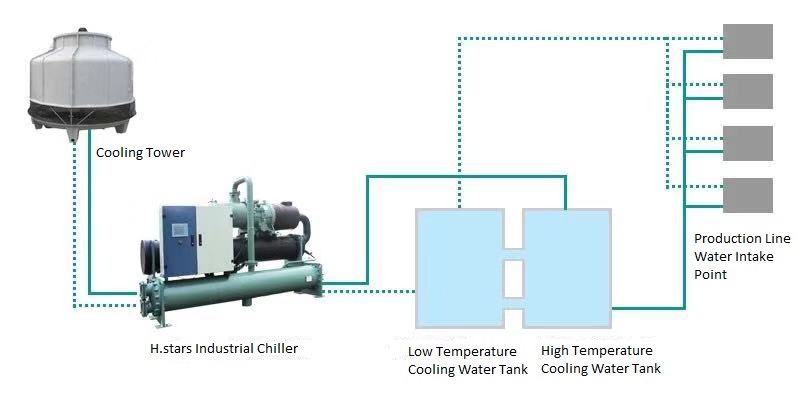

Due to the different ice water temperatures required by the production line, in order to reduce operating costs, chillers and ice water systems are selected according to different temperatures.

Ⅳ.Equipment selection

1.Main Equipment:

The 5 degree ice water system selected one H.stars water-cooled industrial chiller (model 40STD-2020WDI2, cooling capacity 2016KW, input power 348.4KW), equipped with one cooling tower.

2.Main Equipment:

-5 degree ice water system selected one H.stars water-cooled industrial chiller (model 40STD-1090DSM2, cooling capacity 824KW, input power 239.9KW), equipped with one cooling tower.

3.5 ℃ ice water unit equipped with cooling tower*1 unit

4. -5 ℃ ice water unit equipped with cooling tower*1 unit

5.Cooling water pump:

5℃ cooling system supporting cooling water pump*2 units

-5℃cooling system supporting cooling water pump*2 units

6. Chilled Water Pump:

5 degree cooling system supporting chilled water pump*2 units

-5 degree cooling system supporting chilled water pump*2 units

Ⅴ.Use and Control

1. The use and control mode of 5 degree ice water and -5 degree ice water system is exactly the same, which is divided into cooling water system, ice water inner circulation system and ice water outer circulation system.

2. The chiller, cooling tower, cooling water pump and chilled water pump operate in a one-to-one mode.

Ⅵ. The Advantages of System

1. High efficiency and energy saving:

1.1. With double water tank system, the unit's water temperature is high (5 degrees higher than the single tank system), and the unit efficiency is high (15% higher than the single tank system).

1.2. The water tower and water pump of the unit are in one-to-one mode, which effectively reduces the operating costs of the supporting equipment.

2. Easy to use and long service life:

2.1 The water tower and water pump adopt one-to-one correspondence mode, which is easy and convenient to operate and improves the overall service life of the unit;

2.2 The unit uses microcomputer control, with phase loss, reverse, over current, overload, high and low protection, fault inquiry, fault analysis, memory and other functions, easy to use and maintain management.

Ⅶ. Energy saving analysis

1.Use double water tank to increase evaporation temperature and save electricity costs

This is determined by the performance of the compressor unit. In the case of the same condensing temperature, for every 1 degree increase in the evaporation temperature, the unit cooling capacity is saved by about 3.3%. The use of a double water tank can increase the evaporation temperature by 5 degrees, thus increasing the cooling capacity. 16.5%

2. The one-to-one correspondence mode of the water tower and water pump of the unit can save electricity costs, which is related to the production load rate.

Ⅷ. Conclusion

H.stars industrial chillers are suitable for factories that need cooling water and sanitary hot water throughout the year, not only in the pressure and plastic industries, including: pharmaceutical, electronics, electroplating, chemicals, dairy, photovoltaic cells, food, refrigeration, textile and other industries.

Food and beverage workshop ice water system engineering. The ice water system mainly meets the requirements of ice water on the production line. The required ice water temperature has two, one is 5 degrees ice water; the other is -5 degrees.

Ⅱ. Load Calculation

1.5 degrees ice water total cooling capacity is 1500KW

2.-5 degrees ice water total cooling capacity 750KW

3.12 degree water tank: 2*15m³stainless steel insulated water tank

4.-5 degree water tank: 2*15m³stainless steel insulated water tank

Ⅲ.Design Ideas

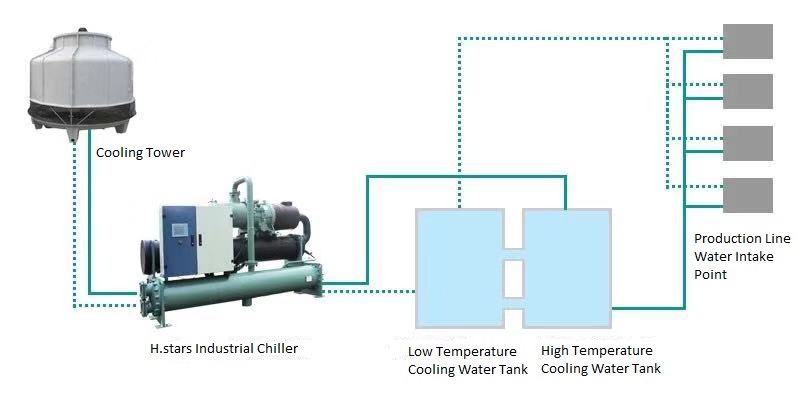

Due to the different ice water temperatures required by the production line, in order to reduce operating costs, chillers and ice water systems are selected according to different temperatures.

Ⅳ.Equipment selection

1.Main Equipment:

The 5 degree ice water system selected one H.stars water-cooled industrial chiller (model 40STD-2020WDI2, cooling capacity 2016KW, input power 348.4KW), equipped with one cooling tower.

2.Main Equipment:

-5 degree ice water system selected one H.stars water-cooled industrial chiller (model 40STD-1090DSM2, cooling capacity 824KW, input power 239.9KW), equipped with one cooling tower.

3.5 ℃ ice water unit equipped with cooling tower*1 unit

4. -5 ℃ ice water unit equipped with cooling tower*1 unit

5.Cooling water pump:

5℃ cooling system supporting cooling water pump*2 units

-5℃cooling system supporting cooling water pump*2 units

6. Chilled Water Pump:

5 degree cooling system supporting chilled water pump*2 units

-5 degree cooling system supporting chilled water pump*2 units

Ⅴ.Use and Control

1. The use and control mode of 5 degree ice water and -5 degree ice water system is exactly the same, which is divided into cooling water system, ice water inner circulation system and ice water outer circulation system.

2. The chiller, cooling tower, cooling water pump and chilled water pump operate in a one-to-one mode.

Ⅵ. The Advantages of System

1. High efficiency and energy saving:

1.1. With double water tank system, the unit's water temperature is high (5 degrees higher than the single tank system), and the unit efficiency is high (15% higher than the single tank system).

1.2. The water tower and water pump of the unit are in one-to-one mode, which effectively reduces the operating costs of the supporting equipment.

2. Easy to use and long service life:

2.1 The water tower and water pump adopt one-to-one correspondence mode, which is easy and convenient to operate and improves the overall service life of the unit;

2.2 The unit uses microcomputer control, with phase loss, reverse, over current, overload, high and low protection, fault inquiry, fault analysis, memory and other functions, easy to use and maintain management.

Ⅶ. Energy saving analysis

1.Use double water tank to increase evaporation temperature and save electricity costs

This is determined by the performance of the compressor unit. In the case of the same condensing temperature, for every 1 degree increase in the evaporation temperature, the unit cooling capacity is saved by about 3.3%. The use of a double water tank can increase the evaporation temperature by 5 degrees, thus increasing the cooling capacity. 16.5%

2. The one-to-one correspondence mode of the water tower and water pump of the unit can save electricity costs, which is related to the production load rate.

Ⅷ. Conclusion

H.stars industrial chillers are suitable for factories that need cooling water and sanitary hot water throughout the year, not only in the pressure and plastic industries, including: pharmaceutical, electronics, electroplating, chemicals, dairy, photovoltaic cells, food, refrigeration, textile and other industries.

评论

发表评论