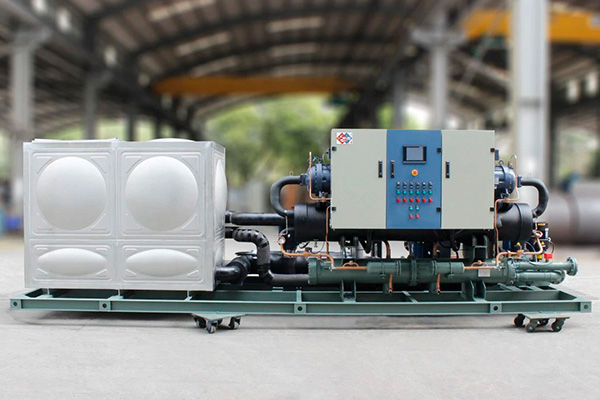

With the increasing demand for cooling technology in industrial and commercial sectors, chillers have become essential cooling equipment in the market. Among these, chiller solutions with water tanks are particularly favored by enterprises due to their unique advantages.

Chillers with water tanks offer high flexibility. This solution allows for adjusting the water tank capacity based on actual needs, meeting cooling requirements for different scales and conditions. Whether in industrial production lines or commercial buildings, chillers with water tanks can provide stable and reliable cooling performance.

These chillers help save water resources. Traditional chiller systems often require a continuous supply of cooling water, whereas chillers with water tanks can reduce water consumption by recycling the cooling water. This not only benefits the environment but also lowers operating costs for enterprises.

Maintenance Advantage: Chillers with water tanks also have maintenance benefits. The circulating cooling water in the tank makes it easy to monitor and treat water quality, ensuring long-term stable operation of the cooling system. Additionally, the design of the water tank facilitates easy cleaning and maintenance of the chiller, enhancing the equipment's lifespan.

These chillers can provide a more comfortable working environment. By adjusting the amount of cooling water in the tank, it is possible to flexibly control indoor temperatures, creating a pleasant working environment for employees. This positively impacts employee productivity and satisfaction.

Chiller solutions with water tanks are favored by enterprises for their high flexibility, water conservation, ease of maintenance, and ability to improve work environments. As technology advances and market demands evolve, these solutions are expected to see broader application and promotion in the future.

About H.Stars Group:

H.Stars Group,30 years Hongkong brand factory ,manufactures a wide range of HVAC equipment: air-cooled chillers, water-cooled chillers, high-temperature heat pumps, AHU, and shell and tube heat exchangers supplying to worldwide 53+ countries. With H.Stars Hongkong brand recognition and 8 subsidiaries industrial chain, H.Stars Group has supplied HVAC products to 500 Fortune companies.

评论

发表评论