Maintaining optimal temperatures in HVAC chiller system components is essential for their efficient operation. Abnormal temperature ranges can signal potential issues that need timely analysis and intervention. While precise temperature measurements might be challenging, manual estimation by touch often helps in detecting these anomalies. Here’s an in-depth look at ten critical temperature points for effective chiller maintenance.

1. Discharge Temperature

Normal and Abnormal Conditions:

• High Discharge Temperature: During summer, the compressor’s discharge temperature is high and untouchable. This may indicate high suction temperatures or excessive condensing temperatures.• Low Discharge Temperature: If the discharge pipe is not hot, it suggests very low suction temperatures or low refrigerant levels, potentially causing valve structure damage or insufficient motor winding cooling.

2. Compressor Shell Temperature

Impacts and Causes:

• Normal Temperature: The shell can be divided into two parts:• Upper Shell: Influenced by suction vapor, it should be mildly warm or slightly cool (~30°C), with possible condensation around the suction pipe.

• Lower Shell: Affected by motor heat and oil friction, it is typically warmer.

• High Shell Temperature: Indicates high suction temperatures (>15°C), causing excessive heat and potentially leading to poor lubrication and increased wear.

• Low Shell Temperature: Indicates very low suction temperatures (<15°C), beneficial for cooling but risky for liquid slugging and poor lubrication.

3. Condensing Temperature

Normal and Abnormal Conditions:

• Normal Operation: The front part of the condenser is very hot, cooling gradually toward the back.• Abnormal Operation:

• Not Too Hot: Indicates wet suction vapor or insufficient refrigerant.

• Too Hot Throughout: Suggests excessive refrigerant, poor ventilation, or high ambient temperatures.

4. Condenser Shell Temperature

Normal and Abnormal Conditions:

• Water-Cooled Condensers:• Shell-and-Tube: Upper shell should be hot, lower part warm. Entire shell not hot indicates insufficient refrigerant.

• Coaxial: Normally very hot; if not, cooling water is insufficient.

• Air-Cooled Condensers: Upper part hot, lower warm. Entire coil not hot suggests insufficient refrigerant or dirty fins.

5. Receiver Temperature

Normal Conditions:

• Cool and Dewy Suction Line: Indicates high condensing temperatures or overcharged refrigerant.6. Liquid Line and Filter Temperature

Normal and Abnormal Conditions:

• Liquid Line:

• Normal: Warm to the touch.

• Abnormal: Hot, indicating high condensing temperatures or excessive refrigerant.

• Filter:

• Cool: Clogged filter causing throttling and cooling.

• Not Hot: Completely blocked filter.

7. Suction Line Temperature

Normal and Abnormal Conditions:

• Normal: Cool with dew.• Abnormal: Extremely cold with excess dew, indicating overcharging or insufficient refrigerant.

8. Expansion Valve and Evaporator Temperature

Normal and Abnormal Conditions:

• Expansion Valve: Cool with dew, quiet refrigerant flow.

• Abnormal: Loud flow sounds or frosting, indicating a blocked filter or faulty valve.

• Evaporator: Cool with dripping condensation, significant air temperature drop.

• Abnormal: Insufficient refrigerant or low valve opening.

9. Outdoor Unit Temperature Requirements

Standard Conditions:

• Normal Operation: Ambient temperatures up to 35°C. Beyond this, performance decreases, leading to possible system shutdown at >43°C.10. Indoor Unit Temperature Requirements

Standard Conditions:

• Maximum Indoor Temperature: Should not exceed 30°C. Higher temperatures increase system load, risking protective shutdowns and reduced lifespan.Conclusion

Proper temperature monitoring and maintenance of HVAC chiller systems ensure efficient operation and longevity. Regularly checking these temperature points and understanding their implications can prevent system failures and optimize performance. Stay proactive in your maintenance routines to master your HVAC chiller systems with confidence.

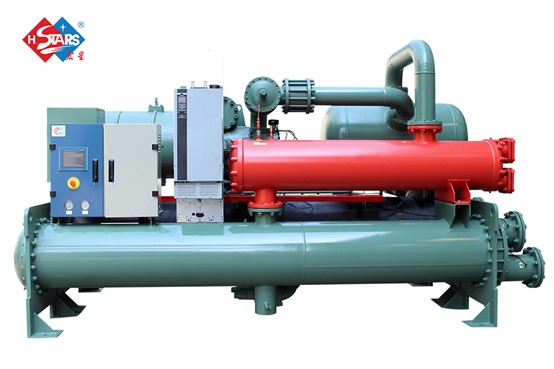

About H.Stars Group:

H.Stars Group,30 years Hongkong brand factory ,manufactures a wide range of HVAC equipment: air-cooled chillers, water-cooled chillers, high-temperature heat pumps, AHU, and shell and tube heat exchangers supplying to worldwide 53+ countries. With H.Stars Hongkong brand recognition and 8 subsidiaries industrial chain, H.Stars Group has supplied HVAC products to 500 Fortune companies.

评论

发表评论