Central air conditioning can be classified into three main types: electric refrigeration air conditioning, lithium bromide refrigeration air conditioning, and other energy source air conditioning. Among them, electric refrigeration air conditioning is the most commonly used form of air conditioning. Let's discuss the classification of electric refrigeration air conditioning in detail.

I. Classification by Cooling Method

Air-cooled: The condenser uses forced air convection for heat exchange. This type is commonly used in residential air conditioners. Air-cooled air conditioners can be categorized into single cooling type and heat pump type. The single cooling type is only used for cooling in summer, while the heat pump type can provide both cooling in summer and heating in winter.

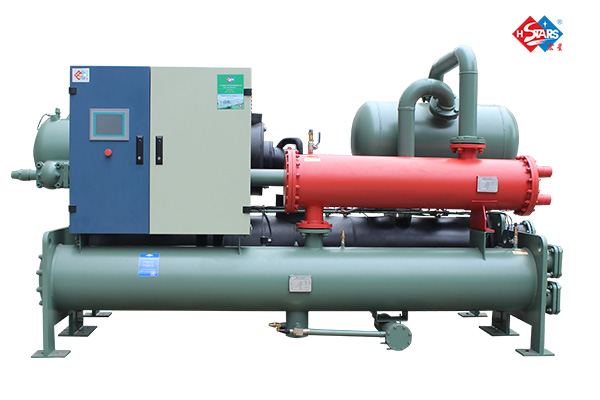

Water-cooled: Heat dissipated by the condenser is cooled using water flow. In order to save water, the cooling water discharged from the condenser is pumped to the cooling water tower, where it undergoes heat exchange with air before returning to the condenser. Water-cooled systems are generally used for cooling only.

II. Classification by Main Compressor Type

Reciprocating Compressor: This type of compressor was widely used in early air conditioners but is now mostly used in refrigeration equipment like refrigerators. Due to its high number of components, it has a higher failure rate, higher production cost, poor stability, and low resistance to liquid impact, making it almost obsolete in air conditioning equipment.

Scroll Compressor: Currently, one of the most commonly used compressors with fewer components, high stability, long service life, and extensive use in small refrigeration units and residential air conditioners.

Rotary Compressor: Previously, most air conditioning equipment used rotary compressors, but in recent years, rotary compressors have become increasingly common in 3-7HP air conditioning equipment, such as multi-split units and household water machines.

Screw Compressor: The most frequently used compressor in large central air conditioning units, characterized by fewer components, high stability, long service life, ease of maintenance, and high energy efficiency, with a minimum energy saving of over 25% compared to reciprocating compressors.

Centrifugal Compressor: Used in large central air conditioning units with high power, featuring high single-unit cooling capacity, simple structure, reliable performance, stable operation, and high requirements for production processes.

III. Classification by Indoor System

Fluorine System: Indoor units and main units are connected by copper pipes through which refrigerant flows. Commonly used in residential and commercial air conditioning systems due to its characteristics, the system cannot be made very large.

Water System: Indoor systems and main units are connected by water pipes through which low-temperature water (7℃) flows back to the main unit after absorbing heat from the indoor unit (fan coil). Widely used in large central air conditioning systems.

In addition, there is also an air system, which is different from the previous two. It directly processes air to the required temperature using an air handler and delivers it to the required rooms through ducts. It is easy to introduce fresh air but has height requirements for installation and is less economical.

IV. Comparison of Common Air Conditioning Unit Cooling Capacities

Screw Water-cooled Chiller: Large cooling capacity.

Scroll Water-cooled Chiller: Relatively less used.

Centrifugal Water-cooled Chiller: Very large cooling capacity.

Air-cooled Scroll Chiller Heat Pump Unit: Large cooling capacity without the need for cooling towers or dedicated air conditioning rooms.

Air-cooled Modular Chiller and Heat Pump Unit: Moderate cooling capacity without the need for cooling towers.

Large Air-cooled Scroll Chiller Heat Pump Unit: Similar to the air-cooled modular form with large cooling capacity.

Small Villa-type Water System Air Conditioning Unit: Small cooling capacity suitable for home use.

Small Variable Frequency Multi-split Air Conditioning Unit: Small cooling capacity suitable for home use.

V. Knowledge of Air Conditioning System Components

Compressor: The core of the entire air conditioning system and the source of system power. The compressor compresses low-temperature gas into high-temperature gas, which then exchanges heat with other media in the heat exchanger. Therefore, the quality of the compressor directly affects the overall effectiveness of the air conditioner.

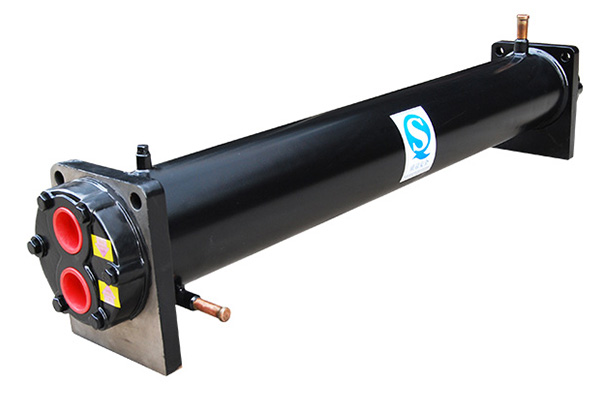

Heat Exchanger: According to its role in the air conditioner, it can be divided into condenser and evaporator.

Condenser: Converts the high-temperature and high-pressure refrigerant discharged by the compressor into liquid or a mixture of liquid and gas. Condensers can be classified into water-cooled, air-cooled, and mixed water and air-cooled types.

Evaporator: Absorbs heat from the cooled medium by utilizing the low-temperature liquid refrigerant's evaporation at low pressure. Evaporators can be classified into those that cool liquid refrigerant, cool air, or other gases.

Throttle Components: The throttle components reduce the high-pressure liquid discharged from the condenser to a lower pressure, causing the liquid refrigerant to evaporate and absorb heat at low pressure.

Throttle components can be classified into capillary tubes and expansion valves. Capillary tubes are used in smaller refrigeration equipment (some small household air conditioners still use electronic expansion valves). Expansion mechanisms used in large and medium-sized devices include expansion valves, such as manual expansion valves, float control valves, and thermal expansion valves, the latter two being automatically controlled expansion valves. Thermal expansion valves can be further classified into electromagnetic expansion valves and thermal expansion valves.

The water-side heat exchanger types used in small villa and modular air-to-water heat pump units include sleeve, plate, and vertical coil types. Integrated units generally use dry shell-and-tube heat exchangers.

In summary, understanding the classification of electric refrigeration air conditioning based on cooling method, main compressor type, indoor system, and other factors provides valuable insights into the selection and operation of air conditioning systems.

H.Stars Group with 30+ years of experience can help you with our advanced HVAC equipment, If you would like to learn more about Industrial cooling equipment, please leave your inquiry on our website, and our sales team will contact you as soon as possible.

评论

发表评论