As an integral part of the hospitality industry, hotels have high requirements for temperature control and fresh air. Various refrigeration equipment is necessary to meet the needs of comfort and food preservation. In this article, we will explore various typical refrigeration scenarios in hotels, along with specific refrigeration equipment used in different settings and their design selection principles.

1.Different Refrigeration Applications and Corresponding Equipment in Hotels

As an integral part of the high-standard hospitality industry, hotels utilize various refrigeration equipment to provide guests with a comfortable and high-quality service environment, including dining experiences. Typical refrigeration applications in hotels include:1.1 Central Air Conditioning System

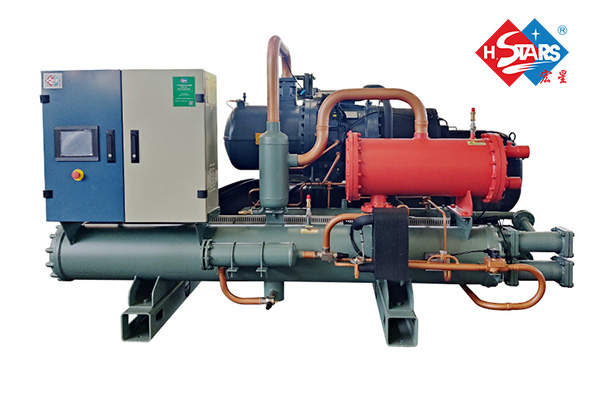

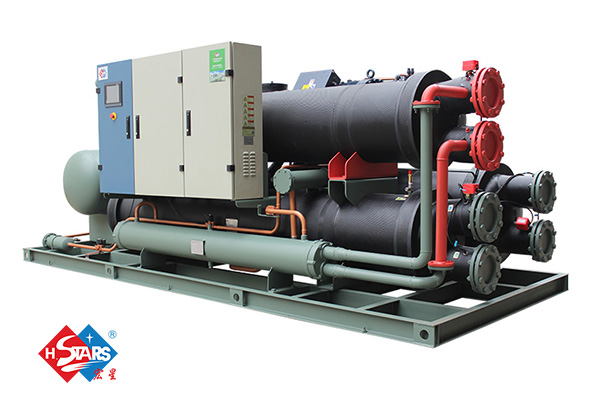

Designing a constant temperature and humidity central air conditioning system to control the temperature in public areas and accommodation spaces such as hotel lobbies, guest rooms, and meeting rooms. Utilizing water-cooled multi-split units and incorporating fresh air treatment.a. Water-cooled screw chiller units: Commonly used in large central air conditioning systems, ensuring efficient and energy-saving operation.

b. Multi-split unit systems: Employing heat recovery technology, independently heating and cooling different rooms to significantly improve energy efficiency.

c. Fresh air treatment system: Treating indoor air supply for dehumidification, ensuring air quality.

1.2 Refrigeration and Preservation in Dining

Hotel restaurants and kitchens require a large number of commercial refrigeration equipment to accurately control the temperature during ingredient storage, refrigerated displays, and food processing.a. Cold storage: Preserving refrigerated foods such as meat and seafood at around -18°C, using reach-in or walk-in units.

b. Ultra-low temperature freezer: Below -30°C, used for long-term storage of frozen food.

c. Refrigerators and display cases: Open or closed refrigerators for displaying and briefly storing perishable items in the front area.

d. Ice maker: Automating the production of ice cubes or ice particles for cooling and preservation in dining.

e. Blast freezer: Rapidly freezing semi-finished food ingredients to maintain freshness.

1.3 Specialized Rooms with Unique Requirements

Rooms with high demands on temperature and humidity control, such as precision air conditioning for data rooms, comfortable air conditioning for hot spring spa rooms, and dehumidification for indoor swimming pool areas.a. Precision air conditioning: Utilizing standalone or split systems with redundant configurations to ensure continuous cooling for data centers.

b. Dehumidifiers: Used in indoor swimming pools, rapidly reducing air humidity through condensation principles to prevent mold growth.

c. Fresh air units: Providing quantified fresh air for spa rooms while simultaneously cooling and dehumidifying to ensure air quality.

1.4 Wine Cellar for Wine Storage

Requiring a refrigeration system to provide a stable low-temperature and humidity storage environment, ensuring the maturation and taste of wines.a. Compressor: Using low-temperature dedicated compressors capable of reaching around -10°C.

b. Evaporator: Large flat evaporators for uniform temperature reduction.

c. Humidifier: Maintaining a relative humidity of 55-75%, avoiding excessive dryness or humidity.

d. Fresh air system: Ventilating the storage environment while filtering and disinfecting the air.

2.Design Principles for Refrigeration Equipment Selection

2.1 Refrigeration Load Calculation

a. Determine design input parameters: Room dimensions, door and window conditions, building envelope structure, lighting conditions, heat generation from equipment, personnel density, etc.b. Calculate heat transfer load: Heat transfer through building envelope structures such as exterior walls, roof, and glass windows.

c. Calculate ventilation load: External fresh air ventilation and internal return air causing load.

d. Calculate internal source load: Consider the heat contribution from people, lighting, and equipment.

e. Comprehensive calculation of sensible load and latent load to determine the total refrigeration system load.

2.2 COP Priority Principle

a. Choose compressors with good refrigerant performance to enhance the efficiency of the refrigeration cycle.b. Increase heat exchange area to improve the heat transfer efficiency of the evaporator and condenser.

c. Optimize the matching of compressors and heat exchangers to maximize the Coefficient of Performance (COP).

d. Pay attention to insulation and control water flow resistance in the refrigeration water system to improve COP.

e. Adopt an economic operation mode to ensure long-term high COP operation of the equipment.

2.3 Reliability Design

a. Design the necessary redundant capacity for the refrigeration system, achieving N+X configuration in critical areas.b. Select core components such as compressors, heat exchangers, and controllers with quality certifications.

c. Implement interlock protection in critical areas to ensure system safety.

d. Adopt technology solutions with long-term operation verification to avoid failures.

e. Monitor system parameters online to ensure reliable and normal operation.

2.4 Intelligent Precision Control

a. Optimize compressor frequency modulation based on changes in indoor load.b. Use Demand Control Ventilation technology in the fresh air system to adjust the fresh air volume.

c. Optimize temperature reset control in the refrigeration water system to match load changes.

d. Utilize predictive algorithms to adjust cooling output based on future load predictions.

e. Implement independent intelligent controllers for different rooms to achieve decentralized control.

2.5 Cost-effectiveness Balance

a. Compare the initial investment and operating costs of different equipment solutions.b. Evaluate factors such as reliability, service life, and maintenance costs comprehensively.

c. Use cash flow analysis to calculate the return on investment for the selected solution.

d. Consider third-party independent consulting for cost analysis.

e. Determine appropriate investment payback period based on the hotel's operating model.

2.6 Environmental Design

a. Use refrigerants with an Ozone Depletion Potential (ODP) of 0, such as R134a, R32, etc.b. Prefer refrigerants with low Global Warming Potential (GWP) to reduce potential global warming impact.

c. Minimize refrigerant leakage during system operation, maintenance, and disposal processes.

d. Choose energy-efficient equipment to reduce the overall system power consumption.

e. Consider environmentally friendly and dismantlable material designs for equipment.

2.7 Localized Solutions

a. Design customized solutions based on specific requirements for different regions.b. Implement specialized systems such as split-type precision air conditioning for key rooms.

c. Use enclosed cooling in data rooms to achieve local environmental control.

d. Adopt zoned control in the fresh air system to adjust based on actual demand changes.

e. Select different cooling system parameters for wine cellars based on the types of stored wines.

2.8 Considerations for Ease of Maintenance

a. Prioritize ease of daily inspection and maintenance when arranging equipment.b. Equip control systems with remote network monitoring functions for fault warning and diagnosis.

c. Implement appropriate redundant designs in critical structures for online repairs.

d. Reserve disassembly space for important components to ensure ease of replacement.

e. Adopt a modular design approach for the system, allowing for quick replacement of key components.

f. Use maintenance manuals to thoroughly document equipment information and maintenance procedures.

g. Establish a standardized maintenance record system for later management decisions.

h. Regularly provide professional training for staff to ensure operational and maintenance proficiency.

i. Sign periodic maintenance contracts with manufacturers to provide continuous technical support.

By scientifically and systematically designing and selecting refrigeration equipment in the complex environment of hotels, not only can various refrigeration needs be met, but also optimization of investment and operational costs can be achieved. This is worthy of close attention from hotel owners and designers.

In summary, hotels, with diverse functions like accommodation, dining, and fitness, require a variety of refrigeration equipment for different areas. Central air conditioning, commercial refrigeration, specialized HVAC for specific rooms, and low-temperature humidification for wine storage are indispensable. When selecting refrigeration equipment, considerations include reliability, energy efficiency, control, and economy to achieve overall comfort and efficient operation. Hotel refrigeration system design and optimization are complex tasks, necessitating collaboration between suppliers and design consultants to offer cost-effective, personalized solutions for owners.

H.Stars Group with 30+ years of experience can help you with our advanced HVAC equipment, If you would like to learn more about Industrial cooling equipment, please leave your inquiry on our website, and our sales team will contact you as soon as possible.

评论

发表评论