In the field of HVAC (Heating, Ventilation, and Air Conditioning), industrial heat pumps play a crucial role in providing efficient heating and cooling solutions. This article aims to explain the fundamental aspects of industrial heat pumps, including their definition, key components, and working principles.

1. What is an Industrial Heat Pump?

1.1 Definition and Purpose:

An industrial heat pump is a device that transfers heat from one location to another using a refrigeration cycle. It operates similarly to a standard heat pump but is specifically designed to handle larger heating or cooling demands in industrial settings. The heat pump extracts heat from a heat source, such as air, water, or the ground, and transfers it to the desired location using a compressor, condenser, evaporator, and expansion valve. Industrial heat pumps play a vital role in HVAC systems by providing efficient and sustainable heating or cooling solutions for industrial facilities, commercial buildings, and other large-scale applications.

1.2 Types of Industrial Heat Pumps:

Industrial heat pumps come in various types, including air-source, water-source, and ground-source heat pumps. Air source heat pumps extract heat from the ambient air, making them easy to install and cost-effective. Water source heat pumps utilize water bodies, such as rivers or lakes, as heat sources or sinks. They offer high efficiency but require access to a water source. Ground source heat pumps, also known as geothermal heat pumps, utilize the stable temperature of the ground for heat exchange. They provide excellent efficiency but require underground installations. Each type has its advantages and suitability for different industrial applications, offering flexible options for efficient heating and cooling.

Air source heat pump

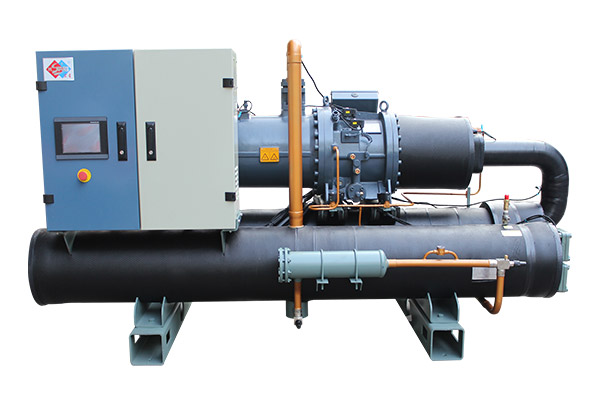

Water source heat pump

Ground source heat pump

1.3 Applications of Industrial Heat Pumps:

Industrial heat pumps find extensive use in various industries and sectors such as manufacturing, food processing, chemical production, commercial buildings, hospitals, data centers, residential complexes, and agricultural facilities. They provide efficient heating and cooling solutions for diverse applications, contributing to energy savings and environmental sustainability.

2. Components of an Industrial Heat Pump:

2.1 Compressor:

The compressor is a crucial component of an industrial heat pump system. It plays a vital role in raising the temperature and pressure of the refrigerant. As the refrigerant enters the compressor, it undergoes compression, resulting in increased energy and higher temperature. This process raises the refrigerant's pressure, which is essential for the heat transfer cycle. By compressing the refrigerant, the compressor enables efficient heat absorption at the evaporator and facilitates the release of heat at the condenser, contributing to the overall heating or cooling process.

2.2 Condenser:

The condenser in an industrial heat pump facilitates the transfer of heat from the refrigerant to the heating medium. As the refrigerant flows through the condenser, it releases heat and undergoes a phase change from a high-pressure vapor to a high-pressure liquid. This heat transfer process enables the release of heat energy to the surrounding environment or the desired heating medium, providing warmth or hot water for various industrial applications.

2.3 Evaporator:

The evaporator in an industrial heat pump is responsible for absorbing heat from the heat source. As the refrigerant enters the evaporator, it evaporates into a low-pressure vapor, drawing heat from the surrounding environment or the heat source. This absorption process allows the refrigerant to capture and carry the heat energy, which is later released during the condensation phase for heating or cooling purposes.

The expansion valve in an industrial heat pump serves the purpose of controlling the flow and pressure of the refrigerant. By regulating the refrigerant's passage from the high-pressure side to the low-pressure side, the expansion valve creates a pressure drop, allowing the refrigerant to expand and cool down before entering the evaporator. This controlled flow and pressure adjustment optimizes the efficiency and performance of the heat pump system.

3. How does an Industrial Heat Pump Work?

3.1 Heat Absorption:

The process of heat absorption occurs in the evaporator of an industrial heat pump. As the refrigerant enters the evaporator, it evaporates into a low-pressure vapor, absorbing heat from the heat source, such as air, water, or the ground. This heat transfer allows the refrigerant to extract and carry the heat energy, which is later released during the condensation phase for heating or cooling purposes.

3.2 Compression:

The compressor raises the temperature and pressure of the refrigerant by compressing it. As the refrigerant enters the compressor, it undergoes compression, increasing its energy and resulting in higher temperature and pressure, making it suitable for efficient heat transfer in the industrial heat pump system.

3.3 Heat Release:

In the condenser, the refrigerant undergoes a heat release process. As it flows through the condenser, the refrigerant transfers heat to the heating medium, whether it's air or water, allowing the heat to be utilized for heating purposes in the industrial heat pump system.

3.4 Expansion:

The expansion valve plays a crucial role in the industrial heat pump cycle. Its primary function is to reduce the pressure and temperature of the refrigerant after it leaves the condenser. By creating a controlled restriction in the refrigerant flow, the expansion valve causes a significant pressure drop. This pressure drop results in the refrigerant expanding and cooling down as it enters the evaporator, where the heat absorption process can begin again. The expansion valve's role ensures the efficient and continuous cycle of the industrial heat pump system.

Conclusion:

Industrial heat pumps are vital components of HVAC systems, offering efficient heating and cooling solutions across various industries.

H.Stars with 30+ years can help you with our advanced HVAC equipment, such as High-temperature heat pumps, Magnetic oil-free centrifugal chillers, flooded type screw chillers,anti-corrosion heat exchangers, flooded Evaporator, falling film evaporators, DX dry evaporator, AHU and etc. If you would like to learn more about high-temperature heat pumps, please leave your inquiry on our website, and our sales team will contact you as soon as possible.

评论

发表评论