A DC Inverter VRF System is a type of Variable Refrigerant Flow (VRF) system. It is a type of air conditioning system that uses DC Inverter technology to optimize the operation of the system and reduce energy consumption. Unlike conventional AC systems, the DC Inverter VRF system has a variable speed compressor which allows it to provide more precise temperature control and better energy efficiency. The DC Inverter VRF system also has multiple evaporator coils, allowing it to provide cooling for multiple rooms or zones. It is a more efficient and cost-effective solution than traditional HVAC systems, making it an excellent choice for large buildings and commercial applications.

DC Inverter VRF System is a type of heating and cooling system that uses a combination of direct current (DC) and variable refrigerant flow (VRF) technology. This system is designed to provide efficient and reliable climate control for commercial, industrial, and residential buildings. The system works by using a DC inverter to control the flow of refrigerant in order to maintain the desired temperature.

The variable flow refrigerant system consists of two major components: the DC inverter and the VRF module. The DC inverter is responsible for controlling the flow of refrigerant and the VRF module is responsible for controlling the temperature of the air. The DC inverter is the key component of the system as it is able to adjust the refrigerant flow rate in order to maintain the desired temperature. This allows the system to be more efficient and conserve energy.

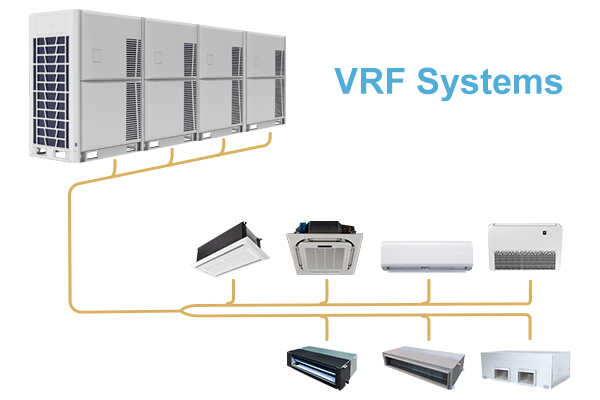

DC Inverter VRF Systems are making waves in the HVAC industry due to their efficiency, reliability, and environmental sustainability. DC Inverter Variable Refrigerant Flow (DC Inverter VRF) Systems are a type of air conditioning system that uses variable refrigerant flow to control the temperature of a space. This system typically consists of an outdoor condensing unit and several indoor evaporator units connected to a refrigerant piping network.

The variable refrigerant flow air conditioning system is a highly efficient, energy saving solution for large-scale applications, such as office buildings, shopping malls, and warehouses. It offers superior comfort to occupants with its ability to precisely control temperature and humidity levels. With the DC Inverter system, individual indoor units can be set to different temperatures, allowing for greater customization. Additionally, DC Inverter systems operate quietly and require minimal maintenance.

One major benefit of the DC Inverter VRF System is its energy efficiency. By using a DC Inverter, the compressor only operates when the indoor temperature falls below the set temperature, allowing for improved energy efficiency. The system also provides a wide range of operational modes, such as cooling, heating, and fan-only. This allows users to select the most.

评论

发表评论