The 21st century is a century of rapid technological development. The global population has exceeded 6 billion, and the shortage of land resources has increasingly become a common concern of all countries. The utilization of underground space will also be paid more attention. Country's tunnel construction has achieved leap-forward development in recent years.

As of 2019, there are 56 cities in mainland China with a total line size of 6,902 kilometers. Among the 6,902 kilometers of construction lines, underground lines are 5,632 kilometers, accounting for 81.6%, and ground lines are 416 kilometers, accounting for 6%; elevated lines 853.2 Kilometers, proportion, 12.4%;

The estimated demand for water-cooled screw chiller in this market is USD 5 million per year. At present, we have a model case and hope to achieve excellent performance in this sub-industry. H.Stars Group has invested capital in this industry since the last few years .

Below is one of H.Stars Group projects done details for reference.

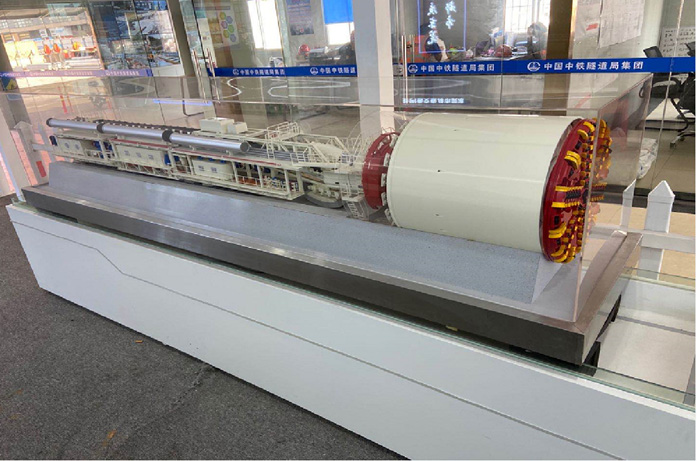

The tunnel excavation works underground, the working environment temperature is high (35~42 degrees), the air is hot and dusty. The operating surface of the shield machine needs to maintain a temperature of about 30 degrees.

We send cold air, comfort and health protection for the staff.

1. It is integrated and small in size. It adopts a Integrated Water-cooled Screw Chiller. The chilled water pump and its electric control are integrated into an integrated unit in the factory to reduce the equipment placement space and installation work on site.

2. The operation is stable and reliable, and the special compressor for high temperature is adopted.

3. The condenser is designed with large temperature difference and small flow to solve the problem of insufficient cooling water flow for customers.

4. Intelligent management, microcomputer control, cloud service, remote monitoring of mobile phone APP.

5. Easy installation and maintenance. The unit has been filled with refrigerant and lubricating oil before leaving the factory. Customers only need to connect the inlet and outlet pipes and power supply to run.

6. The industrial chiller matchs the high-efficiency condenser, evaporator and brand expansion valve produced by our factory.

7. Air handler with detachable filter for easy cleaning.

For more project details, welcome to contact H.Stars engineer team at sales@hstars.com.cn or visit our site at www.hstarschiller.com

评论

发表评论