Advantages and disadvantages of piston chillers

According to the different types of chiller compressors, industrial chillers can be divided into fully enclosed scroll chillers, semi-enclosed piston chillers, and semi-enclosed screw chillers. All kinds of compressors have their advantages and disadvantages. Today, Omar Refrigeration will take you to talk about the advantages and disadvantages of piston chillers.

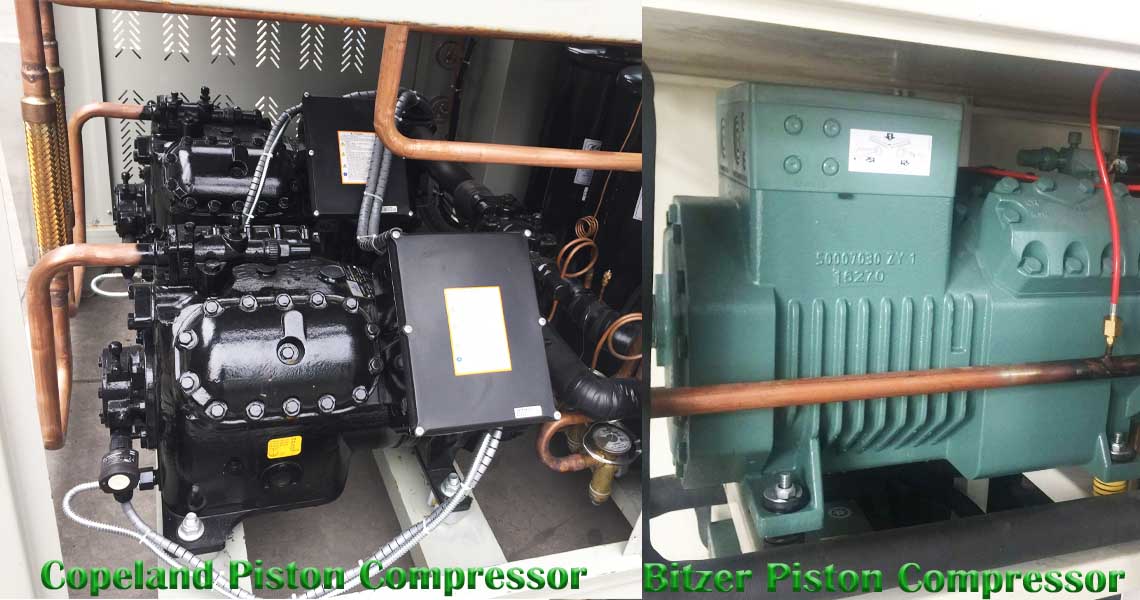

Piston chiller is a chiller with semi-hermetic piston compressor as the main engine. The unit is composed of refrigeration compressors, condensers, evaporators, thermal expansion valves, etc., and is equipped with automatic energy regulation and automatic safety protection devices. The piston compressor device system is relatively simple, and this type of compressor is generally used more in low temperature conditions. For general piston compressors, the brands we use are Bitzer Semi-hermetic Piston compressor, Copeland Semi-hermetic Piston compressor, or Dorin semi-hermetic Piston compressor.

Advantages of piston chillers:

1. Wide range of applicable pressures; strong maintainability.

2. Using multi-head, high-speed multi-cylinder, the performance can be improved.

3. The material is simple, the general metal material can be used, the processing is easy, and the cost is lower than that of the screw chiller.

Determination of piston chiller:

1. There are many parts and wearing parts.

2. The compression ratio is low, the cooling capacity of a single machine is small, and the cylinder unloading adjustment cannot be adjusted steplessly.

3. It has a reciprocating motion up and down, and the vibration is large, and the weight index per unit cooling capacity is large.

4. It is very sensitive to liquid shock.

评论

发表评论