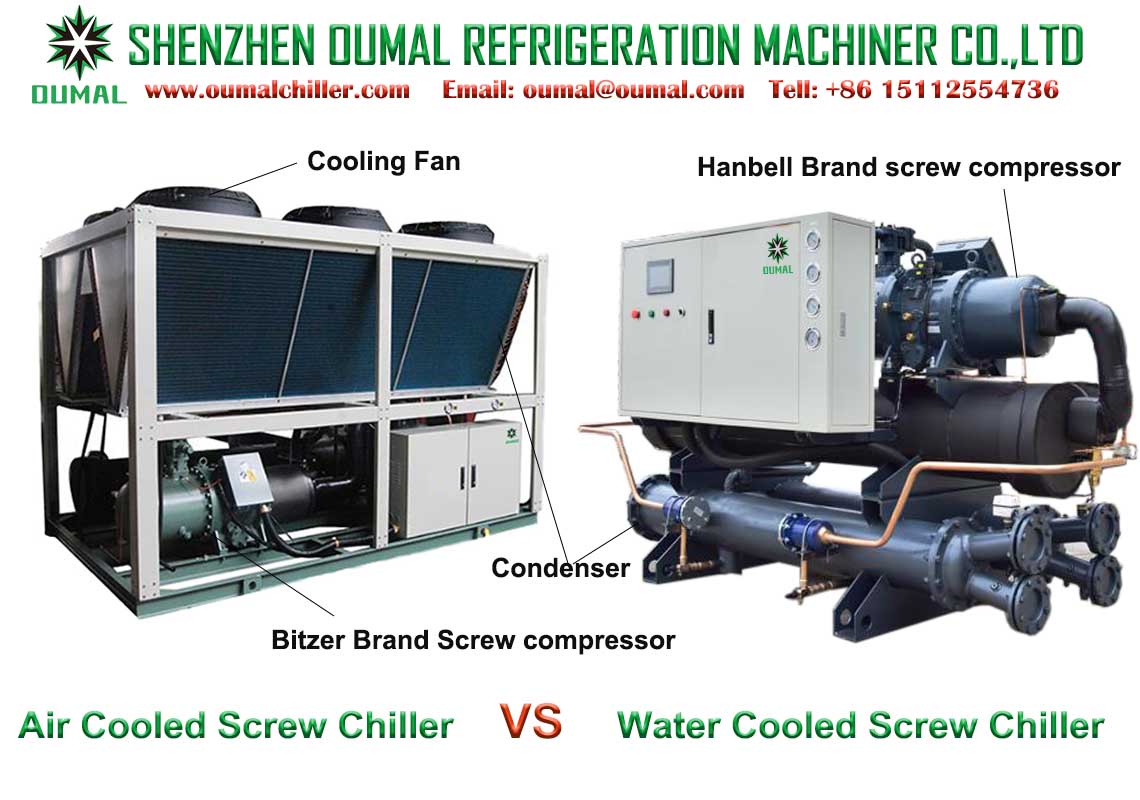

What is the difference between an air-cooled screw chiller and a water-cooled screw chiller - oumalchiller.com

Both air-cooled screw chillers and water-cooled screw chillers use semi-hermetic screw compressors, and screw compressors have a high energy efficiency ratio. At present, the compressors of screw-type industrial chillers mostly use compressor brands such as Hanbell Bitzer, Fusheng, and Refcomp and other compressor brands. The main difference between the air-cooled screw chiller and the water-cooled screw chiller is the form of heat dissipation. The air-cooled screw chiller uses a fan to dissipate heat, uses air as the cooling medium, and dissipates heat through the air through a fin condenser and a low-noise fan. To cool the refrigerant, the water-cooled chiller uses water as the cooling medium, and then the cooling water cools the refrigerant.

Secondly, the installation of the air-cooled screw chiller is simple and does not require a cooling tower. Because the screw chiller machine is relatively large, an external water tank is used. The air-cooled screw chiller is greatly affected by the ambient temperature, especially in some areas with high ambient temperature, which will cause poor cooling effect and may cause a high-pressure alarm due to excessive temperature. As the air-cooled screw chiller’s water quality requirements are small, so we recommend installing an air-cooled screw chiller where the water quality is not good. The water-cooled screw chiller is not affected by the environment, and the cooling effect is better than the air-cooled screw chiller. In the case of the same cooling capacity, due to the lower condensing temperature of the water-cooled screw chiller, higher cooling effect, lower power and lower power consumption, the operating cost of the water-cooled screw chiller is lower than that of the air-cooled screw chiller machine.

Therefore, when purchasing a screw chiller, whether to choose an air-cooled screw chiller or a water-cooled screw chiller requires us to consider the environment, installation, and cost. If you are still hesitating about how to choose a chiller, contact us and a professional refrigeration engineer will give you advice. Email: oumal@oumal.com.

评论

发表评论