As we know that the simplest way to build heating system for hot water for dormitory is adopting boiler with coal burning ,which will cause CO2 increase for the earth. Here is the good example how to design the heating system with energy saving heat pumps to protect the environment.

The project is the central air conditioning project and hot water project of a pharmaceutical factory dormitory building, canteen. The dormitory building has a total air conditioning area of 5700 square meters, 200 people and the canteen area of 1044 square meters. In the original design institute scheme, 14 air source heat pump units are used in the dormitory building, 4 air source heat pump units are used in the canteen, and the machine rooms are located on the roof of each building. Our company has optimized the system design:

(1) The dormitory building and canteen are combined into one system

(2) The system adopts air source multi-functional unit.

Project requirements

Name | Area | Air conditioning cooling load | Air conditioning heat load | Hot water load |

Dormitory building | 5700m2 | 615kw | 308kw | 800kw |

canteen | 1044m2 | 185kw | 96kw | \ |

Project design

1. Cold and heat source designThe system adopts two sets of R1234ze air source multi-functional units, with a total refrigerating capacity of 614kw and a total heating capacity of 652kw, which are used for cold and hot water of air conditioning in dormitory buildings, canteens and sanitary hot water in dormitory buildings

2、 Supply and return water temperature : 7 ℃ / 12 ℃ in summer and 45 ℃ / 40 ℃ in winter; Hot water 55 ℃ ;

3、 Water system design : The closed mechanical circulation system is adopted, and two vertical circulating water pumps (one for use and one for standby) are selected.

Project configuration

Equipment name | Cooling capacity | Power | Heating capacity | Power | Heat recovery | quantity | remark |

Air source multifunctional machine | 307kw | 90kw | 326kw | 85kw | 123kw | 2unit |

Benefit analysis

(1) The air source multi-functional unit is adopted for the combination of the system, and the initial investment cost can be reduced by 25% ~ 30% 。(2) The heat recovery capacity of the unit is 123kw / set, and the unit produces 55 ℃ hot water per hour :M=Q/△T=123kw×1000×0.86/(55℃-15℃)=2.6m3/h, The two units produce a total of 5.2 tons of hot water per hour, saving at least 40% of the operation cost every year

Fuel mode | Fuel unit price | Theoretical calorific value | Comprehensive utilization rate | Hot water cost(RMB/T) | Maintenance cost(Ten thousand/yuan |

Diesel boiler | 6yuan/kg | 10200kcal/kg | 85% | 27.6 | 6 |

Natural gas boiler | 3.5yuan/m3 | 8600kcal/m3 | 75% | 21.7 | 8 |

LPG boiler | 5yuan/kg | 10800kcal/kg | 70% | 26.5 | 7 |

Electric hot water boiler | 1yuan/kwh | 860kcal/kwh | 90% | 48.9 | 5 |

| -- | ---- | -- | 0 | 0 |

(1) One machine with three functions and complete functions; Air conditioning and free domestic hot water are provided in summer, heating and domestic hot water are provided in winter, and domestic hot water is provided in transition seasons ;

(2) Microcomputer control, automatic switching between hot and cold working conditions ;

(3) Equipped with heat recovery, refrigeration and free sanitary hot water ;

(4) When the air conditioning of dormitory building and canteen is used in peak shift, the two systems are centralized into one system, which can reduce the load of equipment allocation, improve the utilization rate of equipment and reduce the initial investment cost ;

(5) The system is highly centralized, and one set of system can meet the needs of refrigeration, heating and hot water and reduce management costs ;

(6) The unit has compact structure, small floor area and simple installation; Reduce initial investment and equipment later maintenance costs

(7) Green energy saving R1234ze refrigerant , ODP is zero and GWP is almost 0.

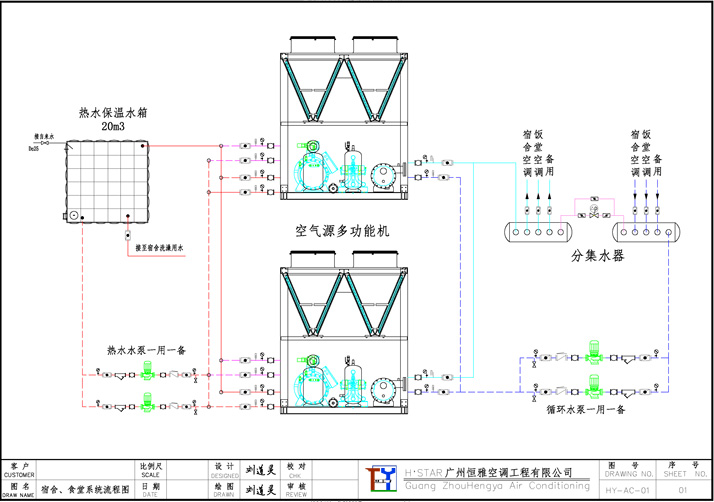

Project system diagram

评论

发表评论