It’s common acknowledged that chemical factory is quite easy cause explosion if all the electrical products don’t handle well. Today we are going to share one of the cooling project with explosion proof chiller system to help you understand How to design a best explosion proof industrial chiller for Chemical factories.

Project OverviewThis project is an industrial cooling project of Chemical Co., Ltd. The content of the project includes:

1. Pure water system: The dosage is 15T/day, and it needs to be reduced from 25°C to 4°C within 8H;

2. Chilled water system: water flow rate is 100m3/h, inlet water temperature is 12°C, outlet water temperature is 4°C;

3. Cooling water system: the water flow rate is 370m3/h, and the temperature difference between inlet and outlet water is 5℃.

The explosion-proof grade of all electrical equipment is required to reach ExdIIBT4.

Equipment configuration instructions

1. The cold source of the pure water system uses a model 20STB-25AD4 air cooled low temperature industrial chiller, and the special manufacturing material in contact with the pure water is made of 304 stainless steel;

2. The chilled water system uses a 40STD-P800WSB4 single-head evaporative cold falling film type large temperature delta chiller with a water inlet temperature of 12°C and a water outlet temperature of 4°C;

3. The cooling equipment uses two HD-200 circular countercurrent cooling towers.

Project Advantages

1. The pure water system uses an air cooled low temperature industrial chiller. The entire unit is completed in the factory. Only the customer's water pipe needs to be connected on site, which is simple and convenient to install.

2. The contact part of the evaporator of the air cooled low temperature industrial chiller unit with pure water is made of 304 stainless steel, without the use of plate heat exchangers, saving the initial investment of the project;

3. The chilled water system uses an evaporative cold spray type large temperature difference chiller. The energy efficiency is the same as that of the flooded type type. The refrigerant charge is reduced by 50%, and the temperature difference between the inlet and outlet water is as high as 8℃. , Improve refrigeration efficiency;

4. The unit increases the heat recovery function, recovering waste heat to provide customers with free hot water for the front stage of steam heating, saving customers operating costs;

5. The unit adopts evaporative condenser for condensing, which has large air volume, good heat dissipation effect, and saves water than cooling tower;

6. The external circulating water pump of the chilled water system adopts frequency conversion control, and uses constant pressure water supply according to the customer's end load, which saves the customer's operating costs.

Equipment configuration instructions

1. The cold source of the pure water system uses a model 20STB-25AD4 air cooled low temperature industrial chiller, and the special manufacturing material in contact with the pure water is made of 304 stainless steel;

2. The chilled water system uses a 40STD-P800WSB4 single-head evaporative cold falling film type large temperature delta chiller with a water inlet temperature of 12°C and a water outlet temperature of 4°C;

3. The cooling equipment uses two HD-200 circular countercurrent cooling towers.

Project Advantages

1. The pure water system uses an air cooled low temperature industrial chiller. The entire unit is completed in the factory. Only the customer's water pipe needs to be connected on site, which is simple and convenient to install.

2. The contact part of the evaporator of the air cooled low temperature industrial chiller unit with pure water is made of 304 stainless steel, without the use of plate heat exchangers, saving the initial investment of the project;

3. The chilled water system uses an evaporative cold spray type large temperature difference chiller. The energy efficiency is the same as that of the flooded type. The refrigerant charge is reduced by 50%, and the temperature difference between the inlet and outlet water is as high as 8℃. , Improve refrigeration efficiency;

4. The unit increases the heat recovery function, recovering waste heat to provide customers with free hot water for the front stage of steam heating, saving customers operating costs;

5. The unit adopts evaporative condenser for condensing, which has large air volume, good heat dissipation effect, and saves water than cooling tower;

6. The external circulating water pump of the chilled water system adopts frequency conversion control, and uses constant pressure water supply according to the customer's end load, which saves the customer's operating costs.

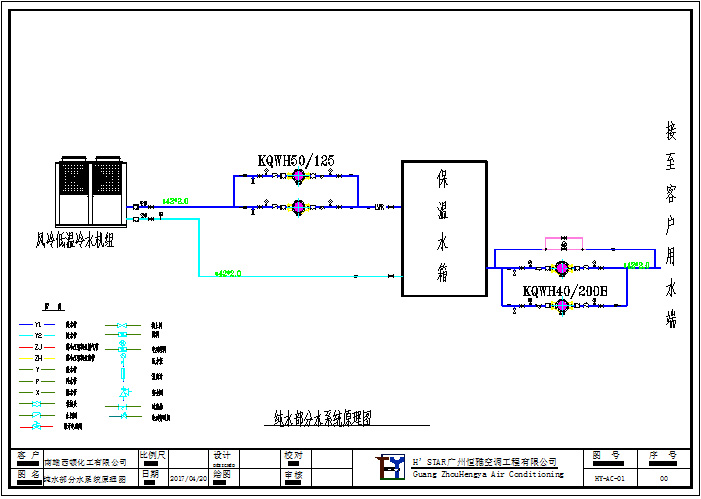

Pure water system diagram

Engineering Picture

H.Stars Group has specialized in manufacturing explosion proof chiller unit since 1992 with high standard. Welcome to contact us for more at sales@hstars.com.cn

评论

发表评论