The compressor is the heart of the chiller, and the normal operation of the compressor is the basis for the normal operation of the chiller. Therefore, if we want to understand the chiller, we must first understand the compressor. Today we will talk about the reasons for the internal protection of the semi-hermetic screw compressor. There is a thermal switch inside the screw compressor. The function of this switch is to disconnect the power supply circuit to the motor of the compressor when the temperature of the compressor exceeds the set value, and the compressor can not be turned on until the compressor is cooled down. And compressor Work. This is the internal protection of the compressor. Today we will talk about the reasons and solutions for this situation.

1.The refrigeration system is short of refrigerant. When the refrigerant is insufficient, the refrigerant returning to the compressor will be overheated, causing the compressor to heat up as a whole, causing the thermal switch to act, resulting in thermal protection of the compressor.

Solution: Add enough refrigerant, and the return pipe of the compressor should be cool when it is turned on.

2.If the condensing pressure of the compressor is too high, the cooling water or the ambient temperature is too high, the exhaust pressure of the compressor will be too high, resulting in the exhaust temperature being too high, and the compressor will be overheated.

Solution: clean the condenser, or increase the cooling water flow pressure.

3.The chiller model we chose is wrong, it is small. When the compressor selection is too small, there will be a small horse-drawn cart, the chiller will never reach the set temperature, and the compressor will continue to work until the compressor is thermally protected.

Solution: To re-select a new chiller, there must be an amplification factor to ensure that the chiller can reach the set temperature and stop.

4.If the compressor motor fails, the insulation of the enameled wire will be poor, which will cause the compressor current to be too large, and it will also be thermally protected.

Solution: Contact the chiller manufacturer to repair the compressor or replace the compressor.

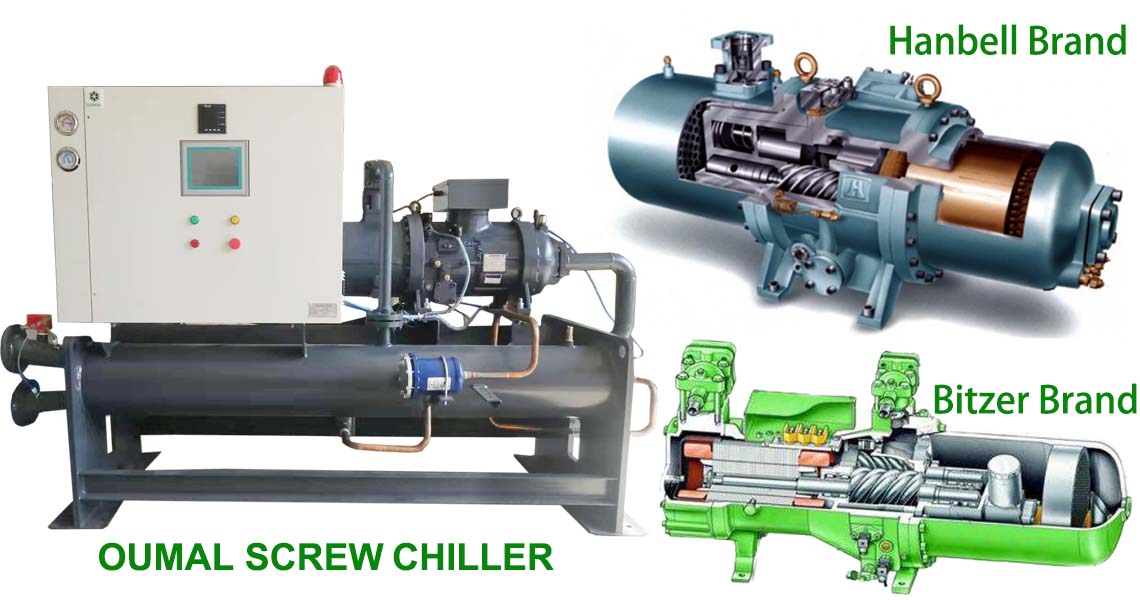

OUMAL CHILLER is a professional screw chiller manufacturer. We use High quality screw compressor Hanbell Brand compressor and Bitzer screw compressor. The Screw chiller type including air cooled screw chiller and water cooled screw chiller from 30 ton to 500 ton. Also including low temperature screw chiller and glycol chiller. If you are looking for a industrial screw compressor chiller please call us to get the latest price.

评论

发表评论