Air-cooled chillers are the most widely used chillers. They are widely used in plastics, electronics, chemicals, metallurgy, video pharmacy, electroplating, leather, crafts and scientific research in industry; they are widely used in hotels in business., Hotels, supermarkets and theaters. Air-cooled chillers are also the easiest chillers to install. Since the entire system of air-cooled water chillers is equipped with fans for heat dissipation, chilled water pumps, and chilled water tanks, customers only need to connect the chilled water inlet and outlet to their own equipment to be chilled to start use.

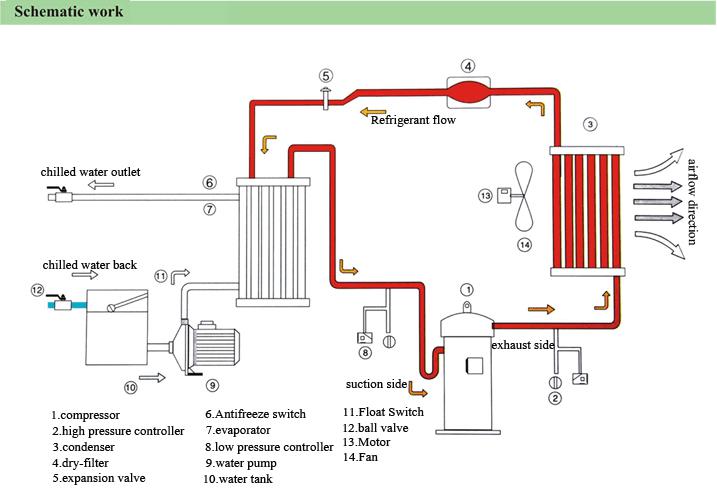

The following is the air-cooled chiller structure:

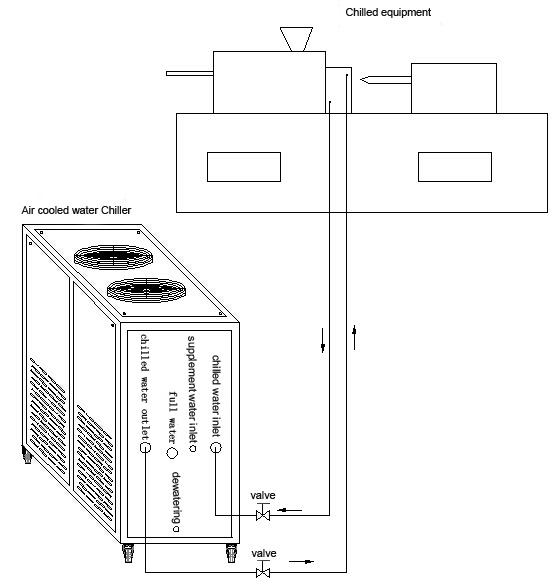

When some customers buy chillers, they worry that they do not know how to install them after they buy them. In addition, the chiller suppliers are far away and it is not inconvenient to install them on site. In fact, these problems are very simple. Oumal chiller specializes in producing chillers for many years. And will provide chiller installation instructions, installation drawings, etc to customers., no need to worry about the installation of air-cooled chillers.

The following is the installation diagram of the air-cooled chiller

Do you know how to install an air-cooled chiller now ? If you have any further questions about installing the chiller, please feel free to contact us. OUMAL can also provide water-cooled chillers, screw chillers, and water-cooled chillers. We will talk to you in the following blogs.

评论

发表评论