A proper water cooled chiller system for UHV electrode foil production line is very essential and important to the industry. However some HVAC engineers still have doubts on how to design a cooling system. Here we will bring a case reference for you.

Project Overview

This plan is designed for the aluminum foil production line one of the Western Electronic Technology Co., Ltd. The project is located inwestern of China. The design requires a cooling system transformation project for 70 aluminum foil production lines. The original process uses groundwater as the cold source, and the groundwater is directly discharged after cooling and heating, resulting in a great waste of groundwater resources. It is now planned to switch to chillers for production line cooling.

According to the use of the project, the design of the aluminum foil production line cooling system transformation plan is to follow the following principles while ensuring that the owner’s needs are met: safety in use, investment costs, energy saving, environmental protection, noise, and cooling system design in accordance with relevant national regulations .

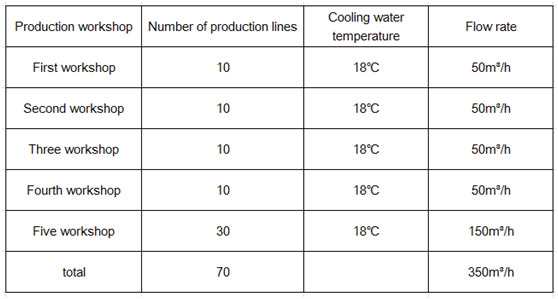

Production line cooling requirements

Brief description of project plan features

1. Dual-mode cooling system design: Taking advantage of the local climate characteristics, it is designed as a dual-mode cooling system. When the temperature is low in spring, autumn and winter, the compressor and related water pumps will stop working, and the energy-saving economizer system will be activated to reduce operating costs;

2. Modular design: each workshop adopts a set of separate cooling system, integrated modular design, the refrigeration host, circulating water pump, heat preservation water tank and control system are made into a whole or several skids, and the main pipelines are installed in the factory , To reduce the amount of on-site installation works;

3. Compressor standby design: the refrigeration host adopts a design of three compressors, each compressor is an independent refrigeration system, two compressors are used in normal use, and one compressor is standby, which reduces the initial investment;

4. Remote cooling water tank design: to prevent freezing of the cooling water pipeline due to low ambient temperature in winter, a remote indoor cooling water tank is added to reduce the operation risk of the unit;

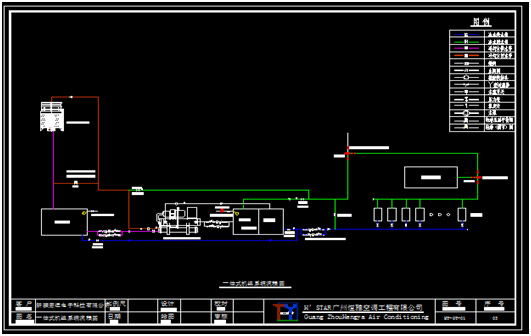

Scheme design flow chart

Installation site

1. Save operating costs, put into use of energy-saving economizers, and save about 1.53 million yuan in operating costs each year;

2. Save investment in spare machines

This plan adopts the compressor backup mode. Each refrigeration unit uses three compressors, and each compressor is an independent refrigeration cycle system. Under normal circumstances, the cooling capacity of two compressors can meet the cooling demand of the production line, and the other compressor The machine is a backup compressor, equipped with a corresponding refrigeration cycle system, and the three compressors can be used in turn to extend the service life of the unit;

3. Save engineering installation costs

One set of refrigeration system in each workshop, the cooling capacity and circulating cooling water are small, the corresponding water pipe diameter is small, the pipeline pipe length is short, and the installation materials and installation costs are greatly reduced;

Above is one of the installed cooling system for UHV electrode foil production line for your reference. If you are interested in more details, welcome to contact H.StarsGroup ,who has got over 30+ years customization service in industrial cooling system design with strong R&D team . Please refer to www.hstarschiller.com or email us at sales@hstars.com.cn

评论

发表评论