Nowadays, as the increasing economy of peoples life, more and more people are in need of ice rink . Therefore, many engineer company is worried about designing a best ice rink refrigeration system with reliability and energy efficient goal. Here are some best suggestions for you before you build an ice rink. Better take a look and it will help you save your time and money.

1. Refrigeration system features

The refrigeration system of indoor ice skating rink usually adopts two refrigeration methods:

1) Direct expansion and indirect cooling. Direct expansion adopts condensing unit;

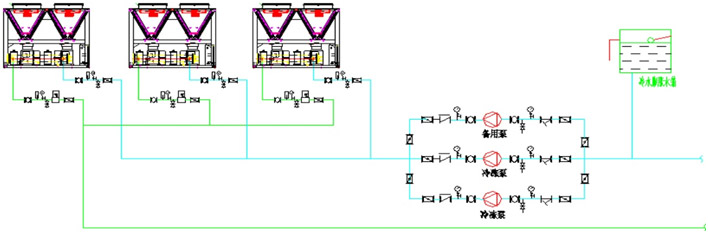

2) Indirect cooling adopts\screw type low-temperature chiller, Glycol is used as a refrigerant to form ice on the rink. At present, uses indirect cooling methods is more popular in the ice rink market. The cooling host should select more than two, one of which can meet the cooling under normal load conditions. When the conditions are relatively bad or the operating host needs to be repaired, the other one can replace the operating host to work.

The unit can increase heating recovery devices, use condensation heat provide to the ice rink and Heating and melting ice crumbs under the floor. The brine pipe network usually uses low carbon seamless steel pipe with a size of 38mm * 3.5mm or a thin-walled polymer pipe with a diameter of 25mm, and the spacing between pipes is about 89~102mm. In order to ensure the smoothness of ice surface, usually used the support to make the pipe network level and fix its position.

In order to make the coolant evenly distributed in the pipe, the size of the collector tube is generally selected bigger so that the brine can pass through low speed and evenly enter each tube. Brine circulation system should adopt closed cycle to reduce pipeline corrosion. besides, the expansion tank should be set up to suit the change of brine volume with temperature.

2. Calculation of refrigeration load in ice field

The artificial ice load is divided into initial freezing load and maintaining load. Generally, it is based on experience and measured data. Load calculation methods include empirical data method, chart method, sub item calculation method, etc.

Reference to American ASHRAE indicators

3. Type selection of refrigerating mainframe

The hardness of the ice surface determines its hardness. Generally speaking, the hardness of the ice surface at -5 degree can meet the requirements. To meet the requirements of ice temperature -5 C, the ethylene glycol solution in pipe of the ice field is set at -15 C.

At present, “Hstars” brand has water cooled screw-type low temperature water chiller and air-cooled screw-type low temperature water chiller can choose, also be used without the standard selection of water pump and expansion water tank. it can work immediately at site after Connect pipe and electricity, It can also increase the heat recovery device, make the hot water at the same time, that will improve the economic efficiency.

4. Air conditioning design for indoor artificial ice field

4.1.Special problems to be considered in air conditioning design of indoor ice skating rink

1. Summer indoor air conditioning design is suitable for dry bulb temperature and

relative humidity.。

2. Air conditioning design should avoid condensate formation on the inner surface of the roof or ceiling

3. When the skating rink doubles as another ball game or training, the air conditioning system design and airflow organization of the indoor skating rink should also meet the requirements for the use of other functions.

4. should make full use of the amount of cooling that is distributed in indoor ice rinks

4.2 Air conditioning professional requirements for civil design

1. In the civil construction must have good thermal insulation measures

2. Enclosure structure should choose insulation materials with good insulation properties and low water absorption, and pay attention to the level of the gas barrier.

3. From the viewpoint of energy conservation and prevention of condensation, the windows on the walls should be made of aluminum alloy double-glazed windows.

4. Special measures to be considered in the design of air conditioning systems

5. Prevent condensation on the roof or ceiling Common technical measures:

(1)The ceiling of the ceiling is made of aluminum sheet metal.

(2) Increase the surface temperature of the ceiling or roof.

(3) Indoor set dehumidification device or air conditioning system

6. Eliminating ice fog

Use the following technical measures to eliminate ice fog

(1)Reduce indoor wetness.

(2) Send air to the ice.

(3) A dehumidifier or an air-conditioning unit (independent air-conditioning unit with a chiller) is installed in the indoor rink to dehumidify the indoor air and reduce the dew point temperature of the indoor air.

Regarding to above best design of an ice rink , H.Stars Group has specialized in manufacturing ice rink chiller with reliable quality and competitive cost for more than 30 years. For more details ,welcome to contact us at sales@hstars.com.cn

H.Stars Products Photos

评论

发表评论