In 2004, the Ministry of Construction issued a document that chilled water must be used in the concrete mixer projects such as subways, bridges, and dams. The chilled water varies according to the outdoor temperature across the country, and the general temperature is 2℃-7℃ .

H.Stars Group has not been involved in this market before, and customers know little about chillers, so ordinary customers buy ice cubes and ordinary tap water to solve the problem according to production needs. According to relevant statistics, this market is worth more than 3 million dollars per year. At present, only a few concrete chiller plant pays attention to this market. Since the chilled water temperature in this market is 2℃-7℃, the chillers are generally ammonia machines. Competing with other chiller manufacturers in this market, H.Stars Group concrete water chiller can directly supply 2°C water with advantages in terms of technology, equipment, solutions, and services. As long as this market and vigorously promotion to change the traditional concept of customers, H.Stars Group will surely achieve excellent performance in concrete projects such as subways, bridges, and dams.

H.Stars Group Headquarter

Because water chiller for concrete plant cooling is a technique that reduces the temperature of poured concrete to a certain level, in order to guarantee the quality of the concrete. Concrete cooling is mainly used for projects in parts of the world with warm climates, where large amounts of concrete are used. If it cures at temperatures above this level the concrete loses strength, more cracking occurs, it rapidly sets and there is an increased water demand. Therefore, the importance of concrete cooling is huge, especially considering the crucial role concrete plays in almost every building process.

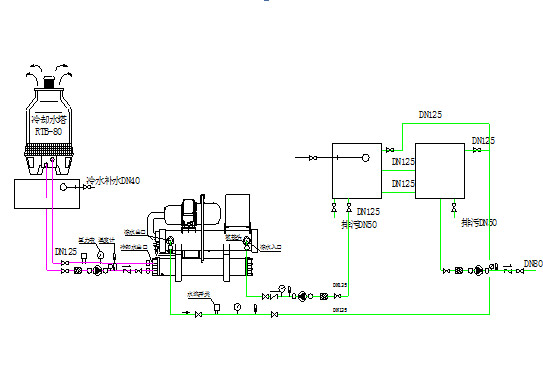

In this scheme, the concrete mixing plant has lots of dust, so there is a buit cooling pond for easy cleaning.Two water tanks must be installed to ensure the outlet temperature at 2℃.

Three advantages of the H.Stars water chiller for concrete batch plant for cement mixer industry:

1.Energy saving-power saving, less power consumption

Example: when water consumption is 16000KG/H, the cost of ice cubes per hour is 100 dollars, and the hourly electricity cost of using the chiller system is 20 dollars, which is a saving of 80 dollars. 24 hours a day can save 1920 dollars.

2.Fast cooling and high efficiency

The chiller directly produces 2℃ water. Use high-efficiency heat exchangers (heat exchangers use double-sided threaded high-efficiency heat exchange tubes to force exchange heat ).

3.Smart operation, simple and convenient

Siemens PLC control to intelligently control the temperature of the outlet water without manual temperature adjustment.

For more details, welcome to contact us at email maychow@hstars.com.cn

评论

发表评论