In general, tube heat exchanger in hot water unit has long life span. Shell and tube heat exchangerstructure: The shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube sheet, baffle plate (baffle plate), and tube box. The shell is mostly cylindrical with a tube bundle inside, and both ends of the tube bundle are fixed on the tube plate. There are two types of heat transfer: hot fluid and cold fluid, one is the fluid inside the tube, called the tube side fluid; the other is the fluid outside the tube, called the shell side fluid. In order to improve the heat transfer coefficient of the fluid outside the tube, a number of baffles are usually arranged in the tube shell. The baffle can increase the velocity of the fluid in the shell side, make the fluid pass through the tube bundle multiple times at a specified distance, and improve the turbulence of the fluid. The heat exchange tubes can be arranged in an equilateral triangle or square on the tube plate. The equilateral triangle is arranged compactly, the fluid outside the tube has a high degree of turbulence, and the heat transfer coefficient is large. The square arrangement is convenient for cleaning the outside of the tube and is suitable for fluids that are prone to fouling.

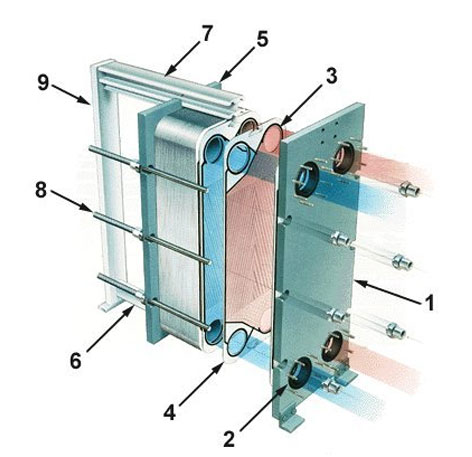

The hot water unit has another type: plate heat exchanger in hot water unit.Plate heat exchanger structure: The detachable plate heat exchanger is made of many stamped corrugated thin plates at a certain interval, sealed with gaskets around them, and overlapped by frames and compression screws. The four corner holes of the plate and gasket constitute the fluid distributor and the liquid collecting pipe. At the same time, the cold fluid and the hot fluid are reasonably separated so that they are separated on both sides of each plate. Flow in the channel and exchange heat through the plate.

In general, coaxial sleeve tube heat exchanger in hot water unit is the cheapest. The coaxial sleeve tube heat exchanger is a heat exchanger in which two tubes of different diameters are sleeved into concentric tubes as components, and then multiple components are connected by U-shaped bends.The advantage of the double-pipe heat exchanger is that it has a simple structure and is suitable for the heat transfer of high-temperature and high-pressure fluids, especially small-capacity fluids. If the process conditions change, as long as the number of bushings is changed, the heat load can be increased or decreased. In addition, as long as the inner tube is made into a sleeve that can be drawn out, dirt can be removed, so it is suitable for fluids that have generated dirt. However, the shortcomings of the coaxial sleeve tube heat exchanger are large flow resistance, large metal consumption, large volume, large floor area, and mostly used for coaxial sleeve tube heat exchanger with small heat transfer area.

评论

发表评论