It is understood that the magnetic bearing chiller is a new type of centrifuge equipment appearing in the international market. Compare to screw chillerIts main characteristics are fast speed, low noise, energy saving, intelligent management, in line with the trend of green development, and the magnetic levitation technology is in the world's leading level.

Magnetic levitation compressor

. bearing sensors detect bearings 6 million times per minute

. make sure that the maximum offset of the shaft does not exceed 7 microns

Automatic control software can compensate vibration error automatically

. bearings up to 48000 rpm, smaller size

Only 2a-4a starting current has no impact on the power grid

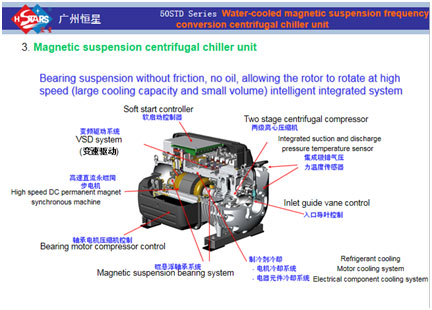

Centrifugal compressor, magnetic bearing without lubricating oil, variable frequency drive, integrated digital control.

Magnetic compressor 9 characteristics

1.The unit controls the water temperature to an accuracy of ±0.1 °C, and the general unit temperature is ±1 °C. It can realize the use of green environmental protection refrigerant HFC-134a, the working pressure is positive pressure, non-toxic and environmentally friendly, no damage to the ozone layer, and safe operation.

2.The unit's integrated part efficiency IPLV is up to 10, and the partial load COP value is over 13. At present, the IPLV of most constant speed centrifugal units reaches 6.3, and the screw chiller is 4.5 (national standard water cooling condition).

3.The whole unit has no oil supply system, which fundamentally solves the problem of system oil return, avoids the oil loss of the compressor, and avoids the heat exchange efficiency of the heat exchanger due to oil coverage.

4.The unit is ultra-quiet operation, the running noise is only 76dB(A), and the noise of the cold-cooled screw chiller reaches 87dB(A). The unit installation does not need to use expensive noise-damping parts.

5.The starting current of the unit is small, only 2A, and there is almost no impact on the grid. The starting current of the cold chiller with the cooling screw reaches 60A.

6.The unit has a compact structure, small footprint, and a unit width of no more than 1.2 meters, which is convenient for installation and saves valuable room area for customers.

7.The unit communication uses Modbus's two-way data exchange, which can be easily and conveniently connected to the customer's selected automatic control system.

8.The compressor has integrated variable frequency control module for easy maintenance and adjusts the magnetic suspension bearing speed according to the load to avoid compressor surge. Compressors are made of aerospace grade aluminum castings and high-strength thermoplastic electronics housings for long-term operation.

9.10%-100% infinite capacity adjustment.

Compare air cooled screw chiller and water cooled screw chiller with magnetic bearing chiller,it can Reduce energy consumption of your air conditioner by 50%

Magnetic levitation technology is mainly for its compressor

The compressor adopts magnetic bearing, which operates under the action of magnetic force, and the shaft rotates without contact with the bearing

Therefore, the energy loss caused by gear transmission is reduced and the speed is higher.

It will not rub the bearings and save the more complex lubricating oil return system.

. bearings up to 48000 rpm, smaller size

Only 2a-4a starting current has no impact on the power grid

When it comes to energy saving, magnetic levitation technology is mainly aimed at the compressor. The compressor uses magnetic bearings, and the shaft rotates without contact with the bearing under the action of magnetic force. Therefore, the energy loss caused by gear transmission is reduced, the speed is higher and the energy saving effect is remarkable.

The data shows that the energy consumption of HVAC accounts for 40% - 50% of the total building energy consumption; in addition, the traditional central air conditioning is just like a range hood. With the increase of service time, the oil path accumulates, the energy-saving effect is reduced, and the later operation and maintenance cost of products is higher and higher. Therefore, energy-saving and efficient central air-conditioning has become an important factor for enterprises to purchase air-conditioners.

评论

发表评论